Posted by John Levan on 5th Aug 2025

Radians Cut Protection Gloves: Advanced Safety for High-Risk Work Environments

When choosing gloves for use in industrial, construction, and manufacturing environments, standard gloves will not provide sufficient protection. Specific hand protection gloves are required because workers in these industries encounter dangerous situations with sharp objects, heavy materials, and machinery creating severe risks of lacerations and punctures.

Radians Cut Protection Gloves serve as the solution for these situations. The gloves provide dependable performance through advanced materials, which match the various protection levels for high-risk jobs.

Why Cut Protection Matters

Hand injuries routinely rank among the most frequent workplace incidents, according to data from occupational safety organizations. Lacerations, which are frequently brought on by contact with blades, sheet metal, or shattered glass, can result in lost productivity, costly compensation, and downtime.

Leading PPE manufacturer Radians responds to these worries by providing a wide range of cut-resistant gloves that are made to be comfortable, long-lasting, and compliant with ANSI/ISEA 105 standards. Radians has a glove for every job, whether it's metal fabrication, HVAC, glass handling, automotive assembly, or warehousing.

Key Features of Radians Cut Protection Gloves

- Variety of Cut Levels

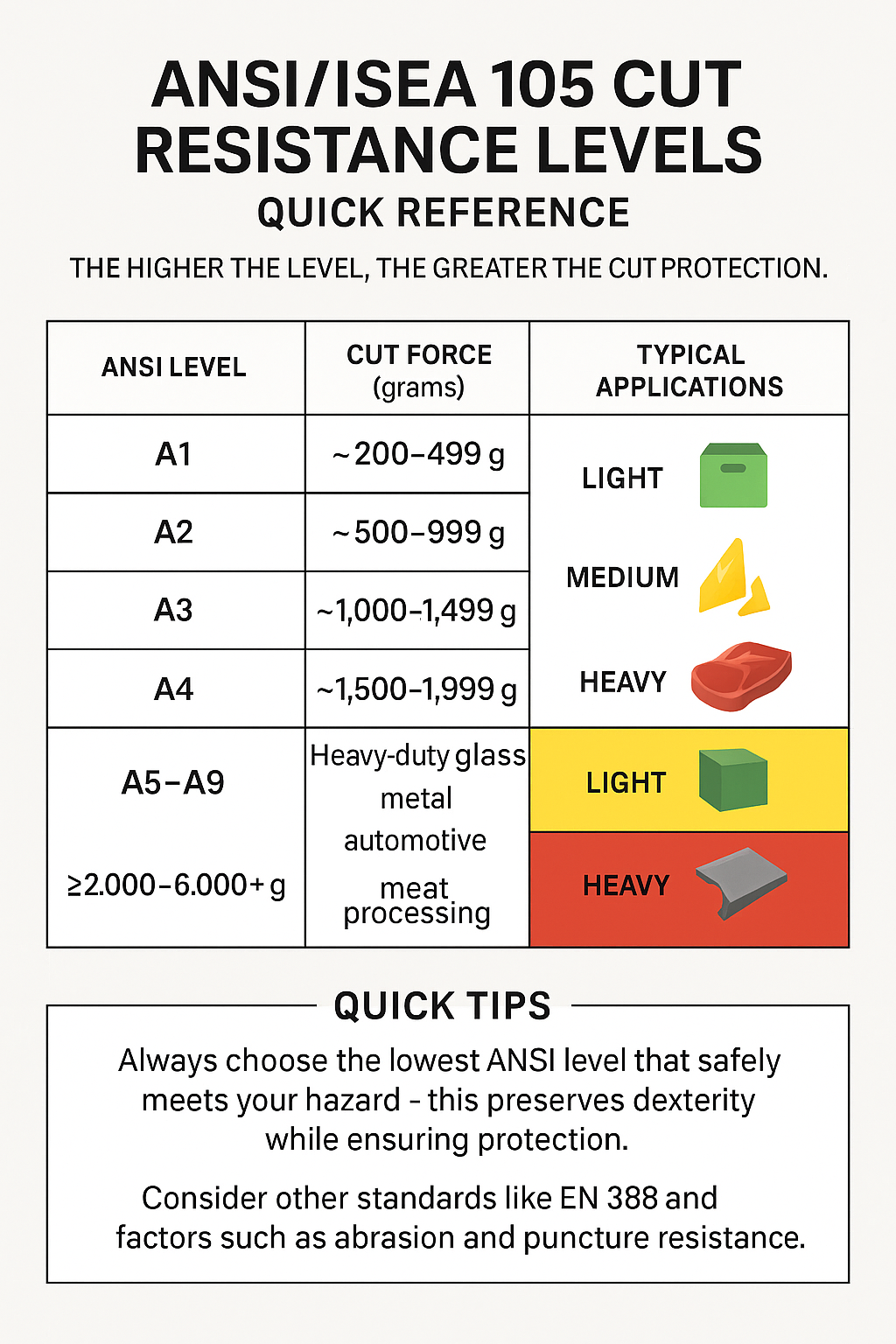

To guarantee that you receive the appropriate degree of protection for the task at hand, Radians offers gloves in ANSI Cut Levels A2 through A9. Although an A2 glove might be adequate for light-duty tasks like packaging or material sorting, heavy-duty jobs involving metal or sharp objects might require A6–A9 level protection.

- Advanced Materials

Radians uses a range of high-performance materials, including:

-

- HPPE (High-Performance Polyethylene): Offers strength without bulk, providing cut resistance while maintaining dexterity.

- Aramid fibers: Used in many high-cut-level gloves, known for excellent heat and cut resistance.

- Steel and fiberglass blends: Deliver top-tier protection for environments with the highest cut risks.

These materials are often blended with spandex or nylon for flexibility and form-fitting comfort.

- Grip & Coating Options

The gloves come with PU, foam nitrile, or sandy nitrile coatings, which provide excellent grip in dry, wet, or oily conditions. The coatings improve both safety and efficiency by enabling workers to maintain control of their tools and materials.

-

- PU-coated gloves: Suitable for precise operations that require touch sensitivity.

- Foam nitrile: Provides a gentle touch while maintaining strong resistance to abrasion.

- Sandy nitrile: Provides a better grip in oily situations and is suitable for mechanical or automotive applications.

- Touchscreen Compatibility

Some models come with touchscreen-compatible fingertips, which enable workers to operate tablets or scanners through their gloves, thus reducing downtime and minimizing cross-contamination risks.

- Comfort-Focused Design

The Radians glove system combines ergonomic design with breathable liners and seamless knit construction to minimize hand fatigue during extended work periods. The gloves include impact protection elements on knuckles and back of hand sections to enhance safety in demanding work environments.

Popular Models

Some standout gloves in the Radians line include:

-

- RWG338 is a heavy-duty A7 glove with TPR (Thermoplastic Rubber) back-of-hand protection and foam nitrile palm, suited for oil and gas or heavy industrial settings.

Compliance and Certification

Radians Cut Protection Gloves are tested to the latest ANSI/ISEA 105-2016 standards and, in many cases, CE EN 388 requirements. This thorough testing gives safety managers peace of mind when specifying PPE for their teams, knowing that the gear meets stringent performance criteria.

Choosing the Right Glove

The selection of appropriate cut-resistant gloves requires more than basic cut level consideration. Consider:

-

- The type of task (sharp tools, oily parts, delicate assembly)

- Environmental factors (temperature, moisture, contaminants)

- The need for grip or impact protection

- Fit and comfort (especially for extended wear)

Safety professionals can find the right glove for their application through Radians' downloadable spec sheets, product videos, and on-site evaluations.

Conclusion

The Radians Cut Protection Gloves deliver hand safety solutions across industries through their innovative design, reliable performance, and affordable pricing. The gloves offer various cut levels, material blends, grip types, and ergonomic designs to help prevent injuries while maintaining worker comfort and productivity. Radians delivers dependable protection to both teams and individual workers during critical situations.