Posted by Guest Post on 28th Mar 2023

Protect Workers from Hand-Arm Vibration Syndrome with CS Unitec Low-Vibration Tools

Any worker who has spent an extended period of time working with tools that vibrate knows the negative impact these tools can have. While their harsh vibrations make them very effective at the job they're designed to do, those vibrations also take a toll on the human user. A common problem with vibrating tools is white finger syndrome.

After a prolonged period of use, these tools can turn the fingers most impacted by their vibrations much paler than the rest of the hand. The affected fingers go numb or tingly and impact both the productivity and the health of workers. Low-vibration tools are a big step toward eliminating white finger syndrome.

What is White Finger Syndrome?

White finger syndrome goes by many names. You may have also heard it called hand-arm vibration syndrome (HAVS) or vibration white finger (VWF). Regardless of the name, the condition is a form of a broader condition known as Raynaud's phenomenon. More specifically, it's a secondary form of Raynaud's, which means that it's caused by a known factor. In this case, the known factor is work-related vibrational stress.

| The condition comes in three phases. Initially, the fingers become pale due to a lack of blood flow. Then, they become cold and numb, potentially turning a bluish hue in the process. Finally, as blood flow returns, the fingers become tingly or painful and may become redder before returning to a normal color. |

Who is at Risk of Developing Hand-Arm Vibration Syndrome?

HAVS affects workers who regularly use vibrating hand-held power tools, such as drills, jackhammers, grinders, and chainsaws. Prolonged exposure to high levels of vibration can damage nerves and blood vessels, bringing on the condition. This puts workers at industrial jobs that require frequent use of these tools at higher risk. There are other factors that can increase the risks of developing the condition:

- Cold weather

- Stress

- Smoking

- Certain medications

In one of the landmark studies that prompted governments to take action on vibration exposure at work, it was found that 71% of workers who had been exposed to vibrating power tools for three or more years had some degree of HAVS symptoms.

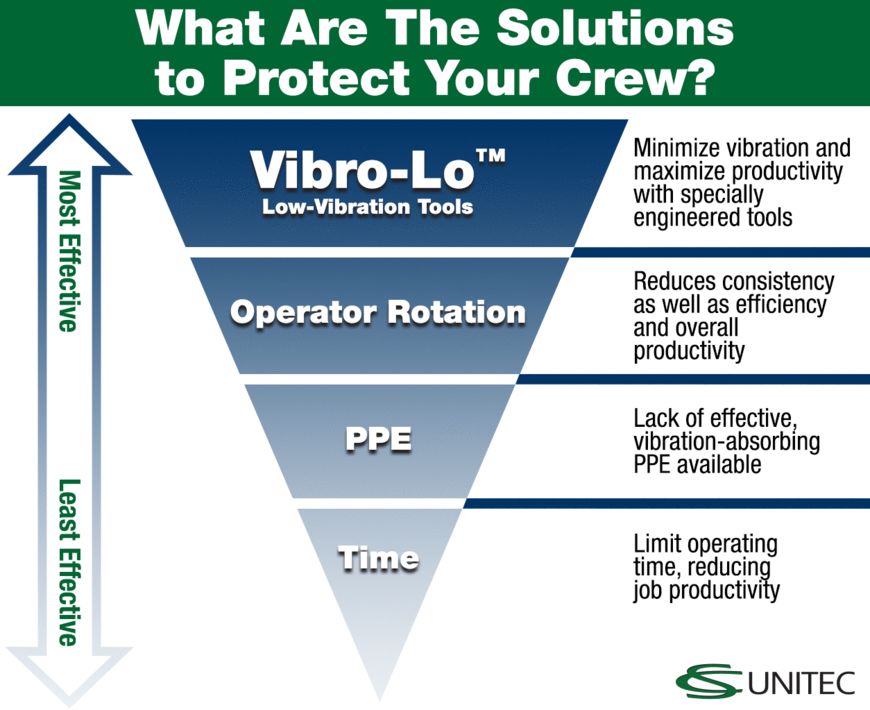

How to Prevent Hand-Arm Vibration Syndrome

In most jobs, avoiding the use of power tools simply isn't feasible. Although productive devices such as vibration-dampening gloves can help, they aren't enough for the type of worker who spends all day with these tools. The better solution is to purchase tools that put a strong emphasis on user safety. Tools designed for low vibration, such as the Vibro-Lo series Needle and Chisel Scalers from CS Unitec, significantly reduce the exposure users have to vibration.

CS Unitec offers a wide range of low-vibration and vibration-reduced tools, including:

- Low-Vibration Pistol Grip Needle Scalers: for texturing and removal of coatings, rust, and adhesive on concrete and metal. Inline Low-Vibration Needle and Chisel Scalers are also available.

- Concrete Scabblers: to roughen, reduce and level concrete surfaces to prepare for coatings and finishes; plus pole scabblers for hard-to-reach applications

- Pneumatic Tampers: quickly compact backfill, asphalt patching and more

- Hand-Held and Floor Concrete Grinders: reduce, remove and smooth concrete surfaces

- Scaling Hammers and Deck Scalers: for removal of coatings and corrosion

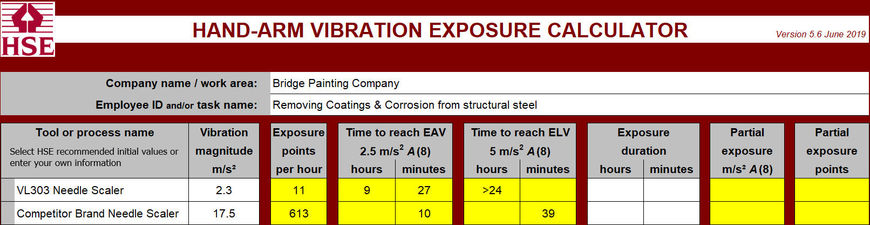

These low-vibration tools can take the exposure time before symptoms of HAVS set in from mere minutes to hours. Over 9 hours, to be exact. This allows crews to be productive throughout their entire shift without fatigue or adverse health risks from excessive vibrations setting in. Several technologies aid the tools in reducing vibration:

- Low-vibration motor - The Vibro-Lo tools are equipped with low-vibration motors that are designed to generate less vibration than traditional motors.

- Vibration-damping mounts - Special mounts help to further ensure that any vibration caused by the motor are other parts of the tools is minimized before reaching the operator.

- Anti-vibration handles - The handles are designed with anti-vibration features that help reduce the vibration felt by users. This includes vibration-dampening materials and ergonomic design decisions.

- Precision-balanced components - Poorly balanced components play a major role in how much vibration is caused by the tool. Vibro-Lo tools precision balanced parts help to eliminate this source of excess vibration.

Legal and Regulatory Requirements for Hand-Arm Vibration Syndrome Prevention

Since governments became increasingly aware of the risk vibrating power tools have on the health of workers, there have been a number of regulatory requirements put in place to limit a worker's exposure to vibration.

- ANSI - The American National Standards Institute (ANSI) has established standards for testing and rating the vibration levels of power tools. ANSI S2.70 sets the methods for determining the vibration emission values of power tools and advice on limiting exposure.

- EU directives - The European Union (EU) has established directives for controlling exposure to vibration. EU Directive 2002/44/EC requires employers to take steps to reduce vibration from hand tools, including the use of PPE and low-vibration tools. It also places limits on the amount of exposure during an 8-hour work day.

| Exposure | Maximum Time of Exposure |

|---|---|

| 2.0 m/s 2 | 12 hours |

| 2.5 m/s 2 | 8 hours |

| 3.5 m/s 2 | 4 hours |

| 5 m/s 2 | 2 hours |

| 7 m/s 2 | 1 hours |

| 10 m/s 2 | 30 min. |

Vibration exposure is measured in meters per second squared (m/s2). The EU directives require a maximum exposure of 5 m/s2 over an 8-hour workday. Any exposure over 2.5 m/s2 must be monitored and controlled. All of the Vibro-Lo tools operate below the 5 m/s2 limit, and several operate under the 2.5 m/s2 threshold.

The Benefits of Using Low-Vibration Tools

Now that low-vibration tools are available, there's little reason to stick with their more aggressive counterparts. The tools perform the same job as older, higher-vibration tools do, but with a number of benefits:

- Reduced risk of HAVS - By choosing a tool designed to reduce the vibrations felt by the user, you'll also be reducing the chances of developing these adverse effects.

- Better ergonomics - Low-vibration tools are more comfortable for workers to use for two reasons: the low-vibration design reduces discomfort, and the design itself is often more ergonomic to begin with.

- Improved productivity - Users of low-vibration tools can work longer before they need a break, allowing your team to get more work done during the workday and be more comfortable doing so.

- Increased safety - HAVS may be the most immediately noticeable safety concern from high-vibration tools, but it's far from the only one. Excessive vibration increases fatigue, which weakens grip strength and reduces concentration, both of which increase the chances of an accident occurring.

- Compliance with regulations - In many countries, employers are required to use low-vibration tools to help prevent HAVS. By investing in low-vibration tools, employers can stay compliant with regulations and avoid potential fines or penalties.

- Lower air consumption - One of the side effects of designing a low-vibration tool is that they also have lower air consumption. This allows for more efficient use of your air compressors, and could even allow for the use of smaller air compressors.

Your typical workday has enough hazards, with the availability of Vibro-Lo technology, there's no need to add excess vibration to the list. Outfitting your team with CS Unitec's line of low-vibration tools can bring a wealth of benefits. To bring the benefits of these innovative tools to your job.

For more information or help selecting the right low-vibration tool for your surface preparation job give us a call at (800) 508-5210 or drop us an email at info@intlairtool.com