7th May 2025

Walter E-Weld Plasma | The Benefits of Walter Anti-Spatter Products

Walter Surface Technologies offers several anti-spatter products that improve welding efficiency and quality while protecting the equipment. The most notable benefits of these products include:

- The Protection of Workpieces and Equipment

Walter anti-spatter products prevent molten metal droplets (spatter) from adhering to workpieces, welding nozzles, fixtures, and tables, safeguarding the welded parts and the welding equipment from damage and contamination. Specialized products like the E-Weld Nozzle provide a ceramic heat shield for MIG welding nozzles, reducing spatter buildup and providing consistent gas flow, which is essential for high-quality welds.

- Time and Cost Savings

By preventing spatter from sticking, Walter anti-spatter solutions eliminate or significantly reduce the need for post-weld cleanup, such as grinding or scraping, saving significant labor time and costs. The product also prevents costly rework and scrap by maintaining the integrity of the weld and the fit of assembled parts.

- Enhanced Weld Quality

Products like E-Weld 4 ensure porosity-free welds and prevent weld defects, supporting cleaner, stronger welds. E4's formulations have thermophobic properties, retracting from the weld seam as heat approaches, which protects adjacent surfaces without interfering with the weld itself.

- Multifunctionality

Specific Walter anti-spatter products, such as E-Weld 3, also work well as cleaners and degreasers. They simplify the preparation process and reduce the steps required before and after welding.

- Compatibility and Ease of Use

Walter anti-spatter solutions are compatible with various metals, including aluminum, steel, and stainless steel. They are easily applied manually or automatically (especially in robotic welding cells) and are effective whether wet or dry.

- Environmental and Safety Benefits

Walter's anti-spatter products are water-based, biodegradable, non-flammable, VOC-free, solvent-free, and silicone-free, making them safer for workers and more environmentally friendly than traditional solvent-based options. Since these products do not leave residues interfering with downstream processes, they do not require special cleaning before painting or coating.

- Reduced Equipment Maintenance

Walter E-Weld Plasma protects cutting tables, fixtures, and welding equipment from slag and spatter buildup, reducing equipment maintenance needs and extending the lifespan of costly components. Walter anti-spatter products streamline welding operations, improve productivity, and support environmentally responsible manufacturing without sacrificing performance.

A Case Study Verifies the Results of Using E-Weld Plasma

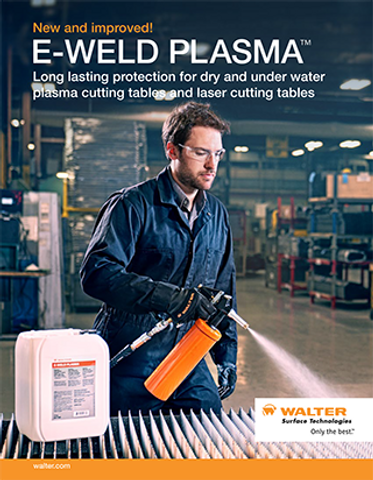

E-Weld Plasma is a ceramic anti-spatter solution applied to dry or wet cutting tables to reduce slag buildup over time. Our air-powered pump sprayer can quickly coat large surface areas.

This simple preventative step keeps slag from adhering to the slats in laser and plasma cutting tables, allowing ease of removal before it builds up and becomes problematic. It significantly reduces the time and effort needed to clean slag from the tables, reducing downtime and saving you expensive labor hours and the associated costs in plant maintenance.

Several case studies by Walter Surface Technologies users confirm the significant results after implementing the Walter E-Weld Plasma solution on the slats of their plasma cutter. Here are their comments:

- "We have a total of 344 hours of table use. (We) can see the difference between the two (coated and non-coated). The operators and I are very impressed with the results so far."

- "We are currently sitting at 884 hours of table use...and the operator is confident that we will get at least another 4-5 months out of the coated slats."

These outcomes were possible with proper prep cleaning before coating with E-Weld Plasma, allowing 5 to 6 hours for the first light coat to dry and applying a second coat with 24 hours to dry.

Check out our Product Pages for order numbers, recommended industries, and additional information.