19th Jun 2023

PFERD Hand Files: Learning the Basics - How to Use Them Effectively and Efficiently

Why choose PFERD Hand Files?

PFERD hand files are world renowned as premium products. PFERD has produced files for over 200 years with the highest quality materials and advanced manufacturing techniques to ensure durability, longevity, and effectiveness. Application-oriented file shapes and cuts for industry and crafts guarantee good economic value. Even after long use, PFERD files achieve high stock removal rates and an excellent surface quality. State-of-the-art production technology and strict quality controls guarantee the outstanding PFERD quality. PFERD is an ISO 9001 certified company.

Uniform hardness through flawless steel microstructure.

The profiling in the rolling mill, the forging of shape and tang, the annealing prior to cutting and the heat treatment each cause a change in the steel microstructure. The high carbon content of the steel microstructure determines the hardness and cutting performance of the file and must therefore be maintained.

Exact shape and uniform cut from tang to tip.

The file blanks acquire their exact shape through forging and grinding. This enables accurate work. Equally spaced teeth and a uniform depth of cut ensure good filing performance and excellent surface finishes. The type and angle of the cut is dependent on the purpose for which the file is intended.

Perfectly milled tooth geometries for every application.

Tooth shapes suited to various applications ensure the best stock removal rate. There is no universally appropriate tooth shape for every application. PFERD has developed the tooth shapes and tooth geometries for each of the various applications. The adjacent figure shows a car body file tooth with its typical rounded tooth face and large flute.

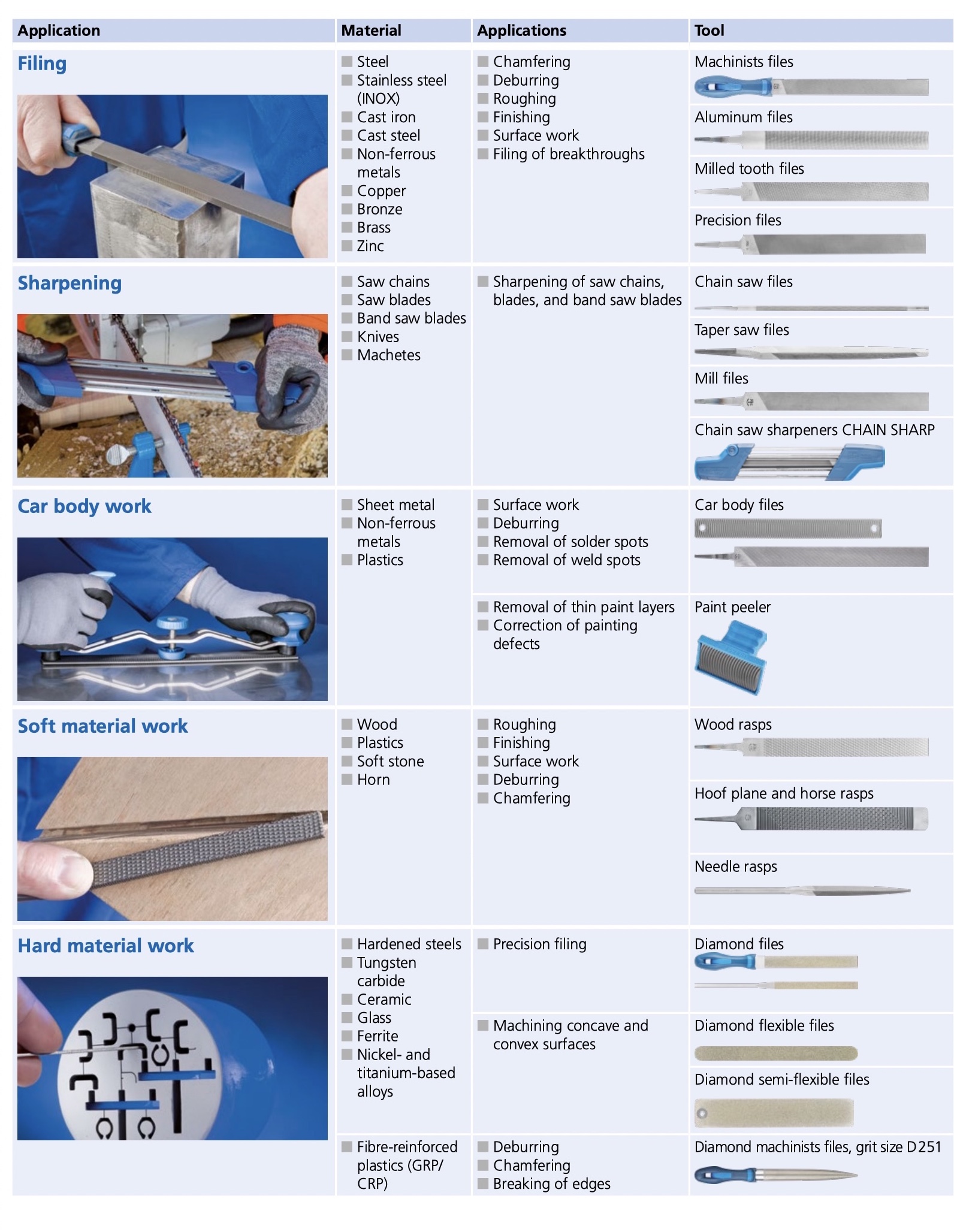

Factors to Consider When Choosing a PFERD File

PFERD hand files have several applications, including chamfering, material removal, roughing, reworking, deburring, finishing, and sharpening. You must find the right file for your intended use to be effective and achieve the desired finish. Doing so also ensures the tool's longevity.

To choose the correct file for your intended use, consider these factors:

- Intended application (Chamfering, Roughing, Surface Finishing, etc.)

- Material you are working with (Steel, Aluminum, Cast Iron, etc.)

- Shape, size, and cut of the file

The effectiveness of your file depends on its combination of cut, shape, and size and its intended use. Considering these factors will help you choose the most effective PFERD hand file. PFERD provides a detailed explanation of hand file cuts and shapes and the intended use of each. It can help in selecting the right file for the job at hand.

Shape

Different file shapes are suited for various applications and offer varying levels of precision and control. For example, you can use a knife or needle file if you want to file tight spaces. If you file flat and curved surfaces, you need a half-round-shaped file.

So, to choose the correct file shape, ask yourself, "What do I need it for?"

Types of Hand Files by Shape

The shape of a file is its physical form or profile of its cross-section.

- Hand files are flat files with a uniform thickness and width from the handle to the tip.

- Flat files are flat on both sides, thicker and broader near the handle than at the tip.

- Round files are cylindrical and may taper in thickness along the length toward the handle.

- Half-round files are flat on the top and round on the bottom and tapered towards the end.

- Triangular files have three flat surfaces and a triangular prism shape.

- Knife edge files are shaped like the edge of a knife.

- Square files have four flat surfaces and may taper in width and thickness from the handle to the tip.

- Keyhole or needle files are very small and thin versions of the above types.

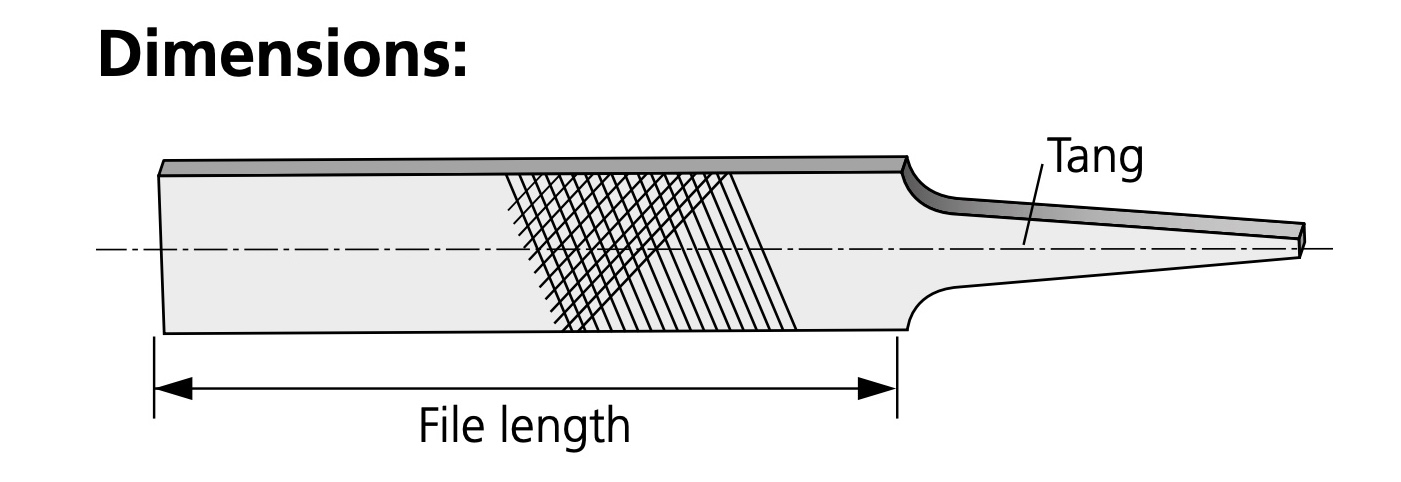

Size

The size of the hand file determines its effectiveness and suitability for various tasks. A larger file can file more quickly than a smaller file, but it can't fit in tight or confined spaces. That means larger files are more suitable for larger surfaces, while small files are ideal for intricate work and smaller-scale projects.

The hand file size also determines how comfortable and in control, you will be when using it, so you should consider that.

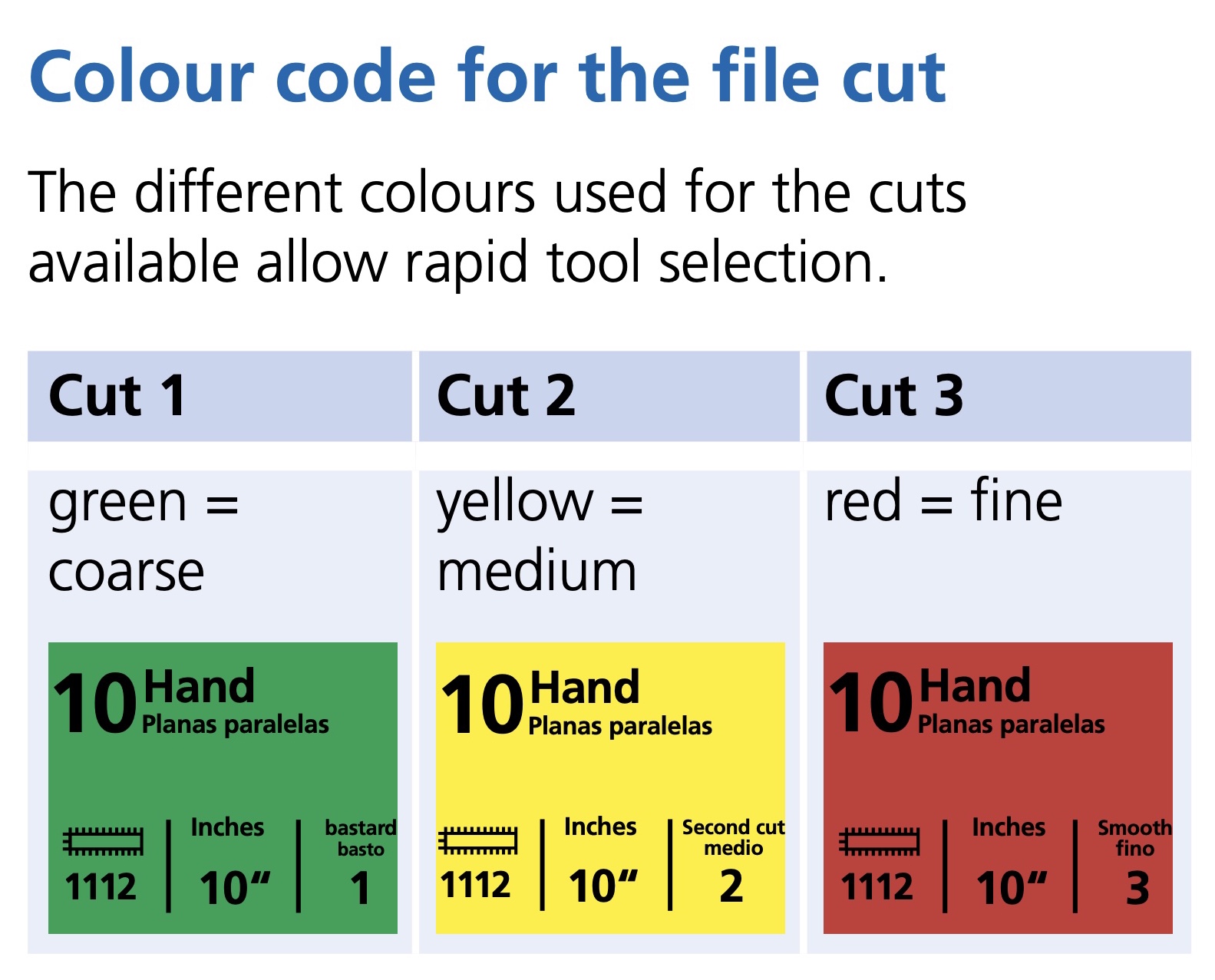

Types of Hand Files by Cut

Cut determines the aggressiveness of the file and the fineness or coarseness of the material it can remove.

- Single-cut files have columns of parallel corner-to-corner teeth.

- Double-cut files have two rows of teeth crossing each other at two different angles.

- Curved-cut files have circular teeth across the working surface.

- Spiral-cut files have round or semi-round cuts.

- Rasp-cut files have triangle-shaped teeth that bulge.

Selecting the appropriate file cut for your application

The tooth pattern and coarseness determine the material removal rate and the surface finish quality. Finer cuts remove materials slower and produce smoother surfaces than coarser cuts.

Cut also determines the application of the file. Finer cuts are ideal for softer materials like wood or plastic, while coarser cuts are more suitable for harder materials like metal. Consider that the cut will help you select the appropriate file and achieve the desired effect. For example Pferd American pattern files are large-sized files with a uniform cut. They are primarily used for fast, controlled removal of material for shaping, deburring, and finishing applications. On the other hand, PFERD precision files compared to American pattern machinist‘s files, precision files are smaller, easier to handle, and possess a more precise geometry.

Determining the number of cuts: The numbers of cuts for PFERD files conform to DIN 8349 requirements. The number of cuts for a file is the number of scores (cuts) per cm of file length, counted along the file axis. For cross cut files, the number of cuts is determined by the upper cut.

Example: At a length of 250 mm, a cut 1 file has 9 teeth/cm. A 100 mm long cut 1 file has 17 teeth/cm of file length, however. The higher number of teeth found on shorter files is intended to provide the same ease of use (in terms of force input, guidability and stock removal rate) on surfaces and edges as for a longer file.

How to File Effectively With PFERD Hand Files

This guide discusses all you need to know to effectively file any surface or material. While anyone can file, only people that do it effectively can achieve the surface texture and shape they desire without error, unevenness, or damage. Achieving the desired surface texture and shape enhances aesthetics and improves the functionality and durability of the surface.

How to Handle and Use a PFERD File

Handling and using a PFERD file properly will help you file safely and effectively and ensure the longevity of your file. Here are some tips on how to properly handle and use it.

- Your grip should be firm but not too tight when you hold the file at the handle or tang to allow for control and maneuverability.

- Stand or sit comfortably to avoid fatigue and straining after filing for a while.

- Apply consistent and moderate pressure on the file. Excessive force can lead to unevenness or damage to the surface, while insufficient pressure can lead to ineffective removal.

- Clean the file regularly to prevent debris from accumulating, which can reduce its effectiveness. A wire brush can remove materials built-up in the file teeth.

How Not to Handle and Use a PFERD File (Important)

One common mistake people make while filing is overlapping strokes. That is, filing both back and front. It may not affect the quality of the work if you aren't looking for uniformity, perfection, or intricate details, but it can damage the file.

A file is like a saw blade, cutting only in one direction. The teeth have an angle relative to the surface, known as a rake. A positive rake angle means the teeth are angled forward, while a negative rake angle means they are angled backward.

If your file has a positive rake angle, you should only push it forward and lift it off the surface when you draw it back. If it has a negative rake angle, you should only pull the file backward and lift it off the surface when you draw it forward. The only time the file contacts the surface is in the cutting direction. If it's in contact with the surface during the return stroke or as it moves in the opposite direction, it will round over the top of the teeth, dulling the file.

Filing Techniques

You can use three filing techniques to shape, smooth, or finish a workpiece: heavy, light, and draw filling.

Heavy Filing

Heavy filing involves applying lots of pressure and using aggressive strokes to remove material. The dominant hand holds the tang or handle, and the palm of the opposing hand is placed on the tip of the file. The opposing hand presses down the file to apply pressure, while the dominant hand controls the file's direction.

Instead of heavy filing with a fine-cut file, consider using a file with coarser cuts, as pressing too hard dulls the fine-cut file quicker.

Light Filing

Light filing involves minimal pressure and gentle strokes for a refined finish. The dominant hand holds the tang or handle, and the opposite hand holds the tip by the fingers. Only the thumb of the opposing finger applies pressure while the dominant hand controls the file. This technique allows for greater control, making it ideal for refining surfaces or removing imperfections.

Draw Filing

Draw filing involves turning the file and grasping it on both ends, then sawing it back and front. However, you should only use this technique with single and double-cut files to reduce the chances of dulling.

Maintaining and Caring for PFERD Hand Files

Like any tool, you must maintain your PFERD hand file to ensure optimal performance and longevity. Here are some tips on maintaining and cleaning your hand file.

- Clean the file before, after, and sometimes during use as material fill between the teeth.

- Store it in a dry place and ensure it isn't in contact with other metals to prevent the build-up of rust.

- Use a rust remover to remove rust if it builds up.

- Avoid dropping it, as it may chip or damage the teeth.

- Re-sharpen it if it dulls or replace it if heavily worn.

Following these tips will ensure you continue filing effectively over the life your PFERD hand file.

Shop a wide selection of High-Quality PFERD Files at International Air Tool & Industrial Supply Company

Only people who file effectively can achieve the desired surface texture and shape. To file effectively, you must understand the types of files based on shape and cut and their ideal uses. You must also understand the factors to consider when choosing an ideal file for the intended use. You also need to know the various filing techniques, where to apply them, and how to handle, use, maintain, and care for your file.

PFERD hand files are designed for productivity. They have excellent tooth geometry for an even, consistent cut across the length of the file. They minimize clogging, which improves their efficiency and lifespan. In addition to traditional hand files, PFERD manufactures a range of specialty files for specific applications, like Pferd diamond files for precision work on hard materials like ceramics and Pferd riffler files for tight spaces on dedicated parts. Their superior design and materials make them an excellent choice for precision work, rough shaping, and everything in between.

![]() Click here to shop PFERD hand files

Click here to shop PFERD hand files

![]() Looking for more information about the Pferd Hand Files? Click here to view the Catalog

Looking for more information about the Pferd Hand Files? Click here to view the Catalog

For more information please call (866) 716-7040 or email info@intlairtool.com