17th Dec 2025

Ingersoll Rand CLK Series Light Industrial Hoists | Mid Capacity Air Hoists with Excellent Load Spotting in a Compact Footprint

When you're in charge of an industrial setting, you know that choosing the right hoist isn't just about the numbers on a spec sheet. It's important to choose the right equipment for your workflow, whether you're moving heavy plate sections into fabrication bays, installing precise components during fit-out, or doing regular maintenance. The Ingersoll Rand CLK Series comes in three configurations, each designed to work best in specific situations you encounter every day.

Here is a helpful comparison of the three, considering how things work in the real world.

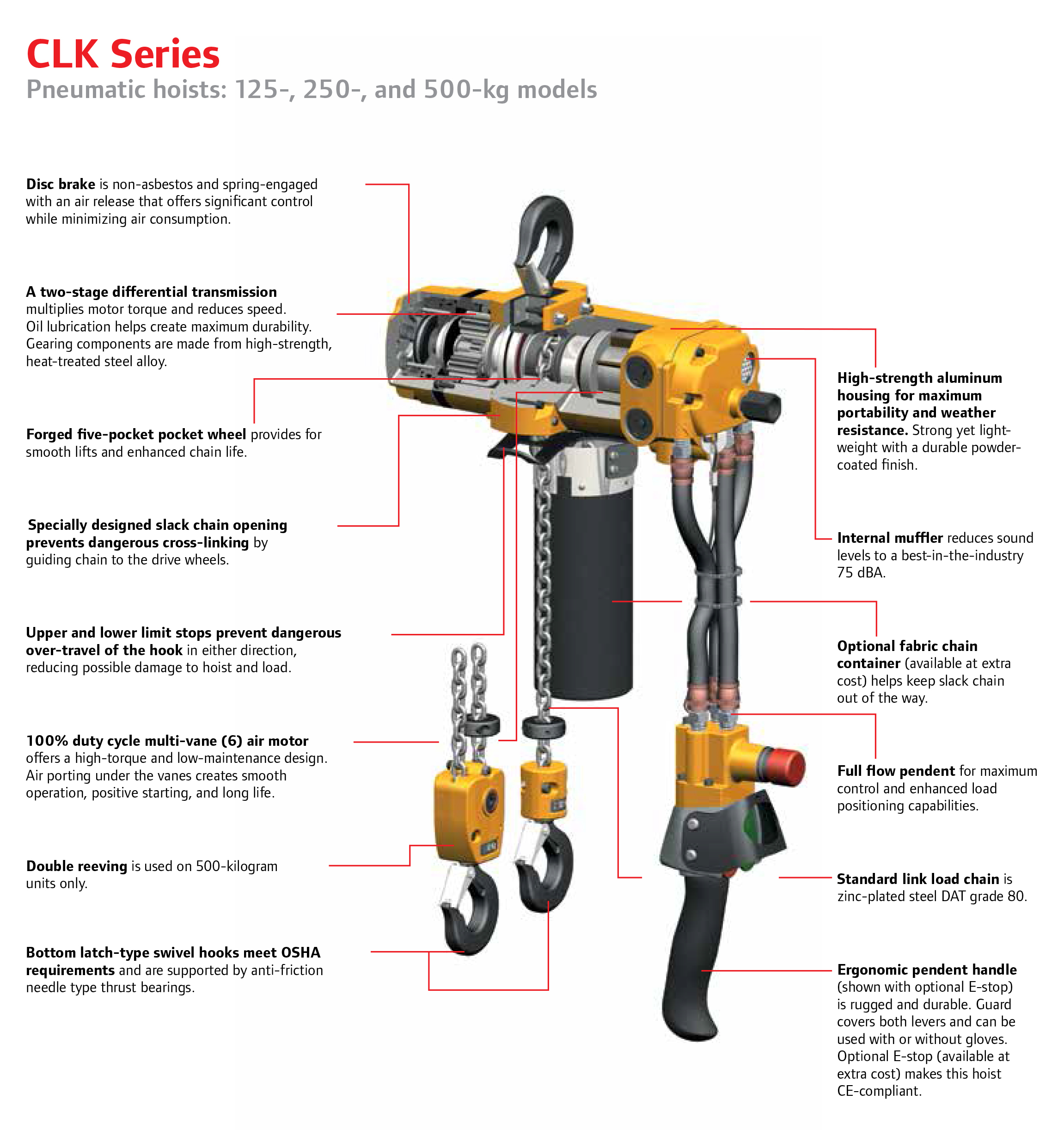

What all three CLK models have in common

Before splitting hairs, it’s worth noting that the CL125K, CL250K, and CL500K share the same core DNA:

- Pneumatic, compact lift air chain hoists are designed for industrial and general utility applications.

- Duty-rated for 800 full-load hours between overhauls with an ASME HST-5 A5 / FEM 1 Am/M4 classification – in plain terms, they’re built for real production duty, not just occasional lifts.

- All models meet ASME B30.16 standards, with a rugged, lightweight, compact design and spring-engaged, air-released disc brake (non-asbestos).

- Quiet operation – around 75 dBA, which helps you keep noise down in already loud environments.

- Typically supplied with a fabric chain container, pendant control, and hook mount for flexible installation.

From a maintenance standpoint, this common platform simplifies spares, training, and troubleshooting. Your team learns the one hoist “family,” then applies it across various capacities.

CL125K (1/8 ton / 275 lbs.): Your light-duty specialist

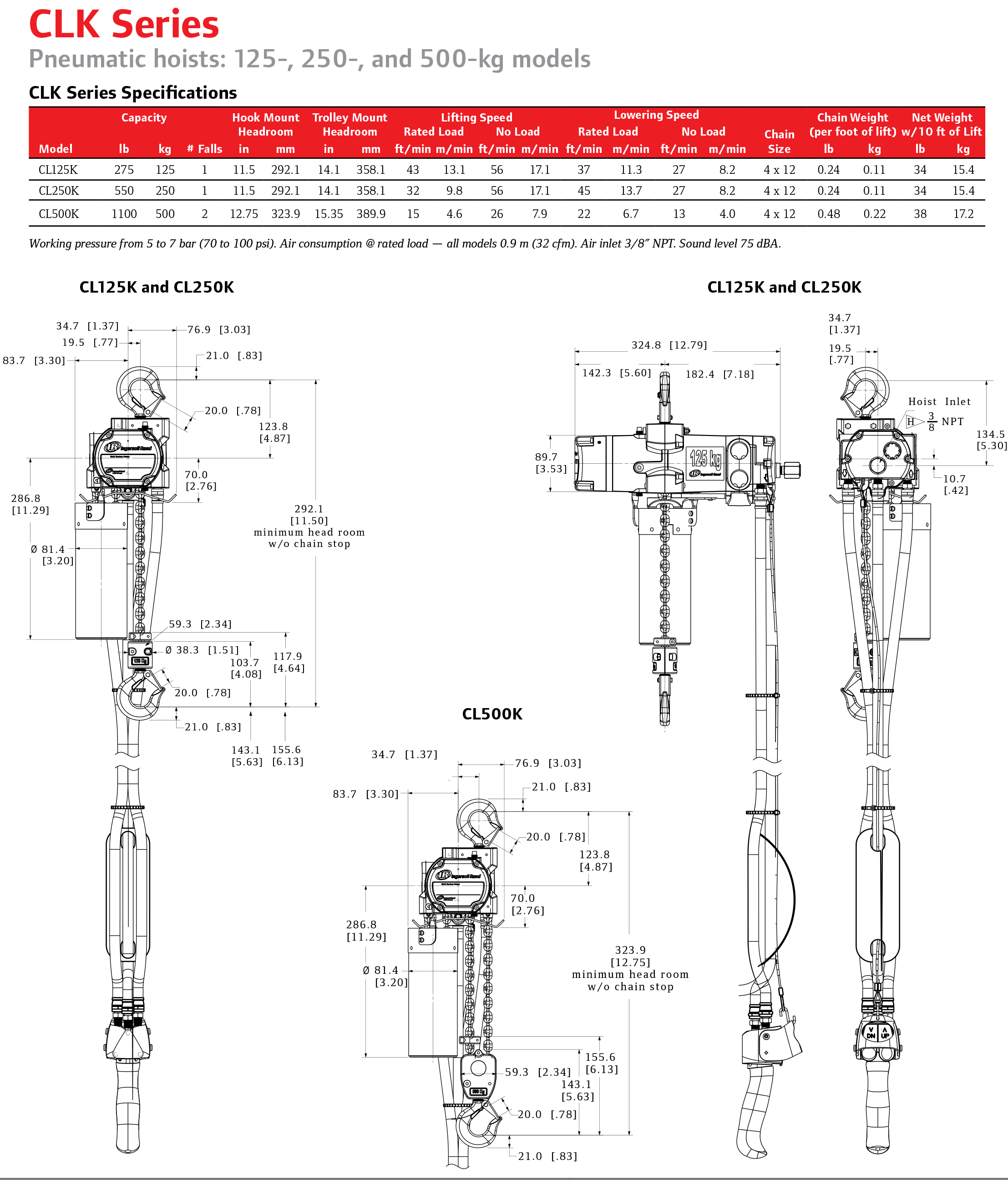

Capacity & performance

- Rated for 1/8 ton (275 lbs.), single-reeved.

- Typical 10 ft lift version runs at about 43 fpm under load and up to 56 fpm no-load – fast for repetitive light lifts.

- Headroom is around 11.5 in, keeping it compact under low structures.

Where it fits in an industrial setting

The CL125K shines where the loads are small but frequent:

- Handling small valves, instruments, and pipe spools at outfitting stations

- Lifting tool boxes, rigging, welders, and small gear sets onto platforms

- Working inside tight spaces – double bottoms, tanks, machinery spaces with limited headroom

If you’ve got technicians constantly handling “only a couple hundred pounds,” this is the hoist that saves backs and speeds cycles. Its higher lifting speed compared to the bigger models keeps throughput up in light assembly areas.

When it’s not enough

Once you get into heavier motors, pumps, winch components, or gearboxes, 275 lbs. disappears quickly. At that point, you’re pushing the upper end of the rating – not where you want to be in an environment with dynamic loads and awkward rigging angles.

CL250K (1/4 ton / 550 lbs.): The everyday workhorse

Capacity & performance

- Rated for 1/4 ton (550 lbs.), single-reeved.

- Typical 10 ft lift model delivers 32 fpm under load, with 56 fpm no-load.

- Headroom remains compact at around 11.5 in, similar to the CL125K.

Where it fits in an industrial setting

For most environments, the CL250K is the “default” hoist capacity for:

- Lifting small to medium pumps and motors

- Handling pipe sections, flanges, and small skids

- Supporting fabrication tables and welding fixtures

From a production manager’s standpoint, this model reduces the “do we have enough capacity?” anxiety without jumping all the way to the larger CL500K and its higher air demand.

When to move up from CL125K to CL250K

If your crews frequently lift 250–400 lbs. items and you find yourself rigging creatively to stay under 275 lbs., the CL250K is the safer, more flexible choice. The minor speed hit vs. the CL125K is generally worth the added margin.

CL500K (1/2 ton / 1,100 lbs.): For serious loads and future-proofing

Capacity & performance

- Rated for 1/2 ton (1,100 lbs.) with double reeving.

- A 10 ft hoist typically runs about 15–16 fpm under load, up to mid-20s fpm no-load.

- Still reasonably compact, with headroom around 12.75 in, but slightly larger and heavier than the 125K/250K units.

Where it fits in an industrial setting

The CL500K is the choice when you’re dealing with:

- Larger pumps and gearboxes

- Steering gear parts and heavier shafts

- Hydraulic power units and large fabrication assemblies

If you’re planning modernization work, retrofits, or expect weight creep in new equipment packages, the CL500K gives you headroom without jumping to a full-size crane solution.

Trade-offs vs. the smaller units

You give up some lifting speed and add air consumption and weight. Operators will notice it feels “heavier” and slower, but if your primary concern is safe handling of significant components, that’s a fair trade.

Choosing the right mix for your operation

In reality, you’re unlikely to standardize on just one of these. A balanced shipyard or maintenance setup often looks like:

- CL125K at small assembly benches, instrumentation shops, and tight spaces

- CL250K in general maintenance bays, pipe shops, and outfitting areas

- CL500K at heavy repair points – engine rooms, pump rooms, machinery shops, and key staging areas on the pier

Since all three share the same CLK platform, you get consistent controls, similar maintenance procedures, and standard spare parts, which simplifies training and reduces downtime when something eventually needs service.

Ingersoll Rand CLK Series Comparison Table

|

Feature |

CL125K |

CL250K |

CL500K |

|

Rated Capacity |

1/8 ton (275 lbs.) |

1/4 ton (550 lbs.) |

1/2 ton (1,100 lbs.) |

|

Reeving |

Single-reeved |

Single-reeved |

Double-reeved |

|

Lifting speed (Loaded) |

~43 fpm |

~32 fpm |

~15–16 fpm |

|

Lifting speed (No load) |

~56 fpm |

~56 fpm |

~23–26 fpm |

|

Headroom |

~11.5 in |

~11.5 in |

~12.75 in |

|

Noise level |

~75 dBA |

~75 dBA |

~75 dBA |

|

Brake type |

Spring-engaged, air-released disc brake |

Spring-engaged, air-released disc brake |

Spring-engaged, air-released disc brake |

|

Duty rating |

ASME HST-5 A5 / FEM 1Am / M4 |

ASME HST-5 A5 / FEM 1Am / M4 |

ASME HST-5 A5 / FEM 1Am / M4 |

|

Advantages |

Fastest speed, compact, ideal for small repetitive lifts |

Best all-around balance of speed and capacity |

Highest capacity, safest option for heavier components |

|

Common uses |

Tools, valves, small spools, outfitting in tight spaces |

Pumps, motors, pipe sections, maintenance |

Gearboxes, winch components, skids, heavier machinery |

|

For managers needing… |

Quick light-duty handling |

A universal “shop standard” hoist |

Extra capacity and future-proofing |

Still unsure which CLK series air hoist to choose for your application? Give us a call and we will help you sort it out.

Our Customer Service and Tech Support teams are available Monday Through Friday from 7:30 A.M. to 4:00 P.M. Pacific Standard Time.

(800) 608-5210 or info@intlairtool.com