Posted by Michael Darooki on 5th Nov 2025

A Guide to Dynabrade Grinders and Their Applications

Dynabrade is a globally recognized brand known for its high-quality abrasive power tools, designed mainly for use in metal fabrication. Designed with precision, durability, and operator comfort in mind, Dynabrade grinders serve a wide range of industries—from aerospace and automotive to foundry and woodworking.

Here's a look at the various types of grinders, including their applications and features:

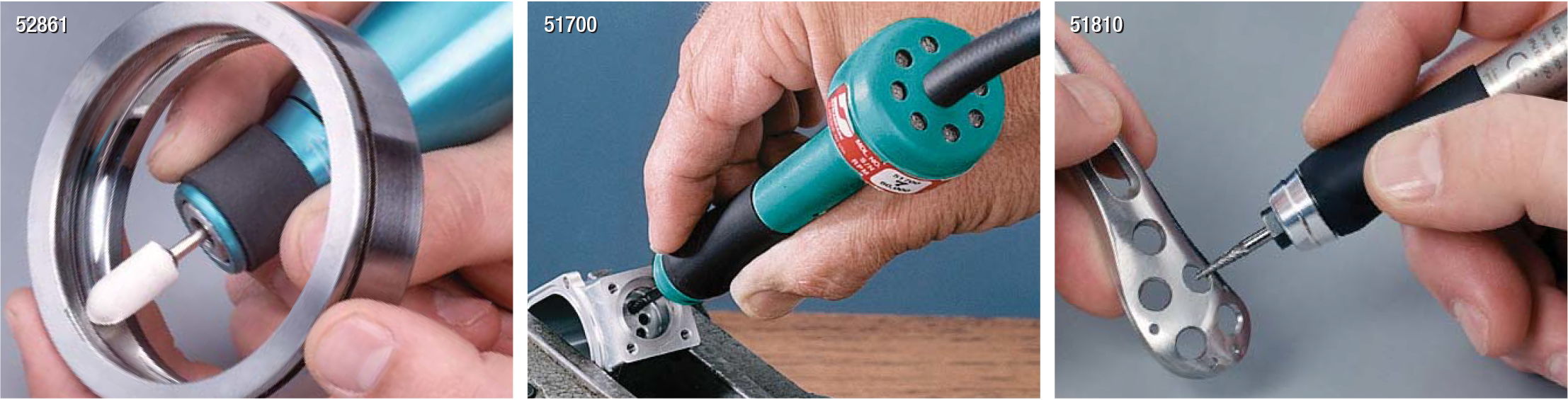

- Dynabrade Industrial Grade Die Grinders

Dynabrade die grinders are compact, high-speed rotary tools that excel in precision material removal or surface preparation work. You can get these tools in straight or right-angle orientation. They run on either air (pneumatic) or electrical power. Their air tools require 90 PSI and all their portable handheld electric tools take 120V.

Applications:

- Deburring: This process is carried out on conjunction with the use of a carbide burr and is the most effective method for removing sharp edges left from the machining or casting process.

- Porting and Grinding: In motor re-building applications, die grinders are used to smooth out the intake and exhaust ports on car engines.

- Surface Prep: Dynabrade die grinders excel in cleaning welds, taking off mill scale, removing rust and paint or even applying scratch patterns to stainless steel.

- Mold Polishing: The name die grinder gets its name from its origin in the tool and die industry. Mold polishing is a common step in tool and die repair and re-work to smooth out complex shapes and cavities that need repair after repeated use.

Key Features:

Most Dynabrade die grinders have adjustable speeds (RPM), comfortable composite grips, and vibration dampening, which makes them comfortable to work with.

- Dynabrade Disc Grinders

Disc grinders utilize a rotating abrasive disc and are available in both horizontal and vertical orientations. Dynabrade offers a wide selection of disc grinders, all of which are application specific and designed for everything from light sanding to weld removal.

Applications:

- Weld blending to smooth out weld seams on metal surfaces.

- Beveling and edge breaking to prepare sharp metal edges for fabrication or painting.

- Surface cleaning to remove corrosion, scale, or old coatings from flat surfaces.

Key Industries:

Disc grinders excel in metal fabrication, shipbuilding, structural steel, and pipeline maintenance.

Advantages:

Dynabrade disc grinders are renowned for their high torque output and safety features, including safety throttles and governor-controlled motors, which ensure steady performance. Some feature a trick vertically mounted motor which takes the place of bevel and pinion gears in the head of the tool. Not only does this decrease weight, but it also reduces maintenance costs. The body of “gearless” Dynabrade disc sanders contains only valving while the motor is flipped upright in the head of the tool

- Dynabrade Belt Grinders – Dynafile and Stationary

Dynabrade's belt grinders use narrow abrasive belts to perform grinding, blending, and finishing tasks on flat or contoured surfaces. They are available in portable handheld models such as the ever-popular Dynabrade 40320, which takes ½” x 18” belts, or in larger, stationary, electric motor-driven configurations.

Applications:

- Tube & Pipe Finishing: Handy for stainless steel handrails and tubing.

- Blending & Polishing: Achieve a uniform finish on both flat and curved surfaces.

- Deburring & Edge Radiusing: Smooth cut edges to reduce sharpness and prep parts for coating or assembly.

The Dynabrade Dynafile® and Dynabrade Pipe Belt Finisher are popular tools in this category. They are known for their flexibility and ease of use in tight or awkward spaces.

- Dynabrade Pencil Grinders

These very light and fast tools are made for precise grinding and detailing in tight spaces. Pencil grinders typically operate at exceptionally high speeds (up to 60,000 RPM), making them ideal for delicate work. Pencil grinders take 1/8” shank accessories.

Applications:

- Engraving & Etching: Precision removal of material for marking or decoration.

- Miniature Deburring: Ideal for aerospace or electronics components.

- Fine Polishing: Achieve micro-finishes on molds, dies, or surgical tools.

Why Use Them:

Because they are small and produce minimal noise or vibration, they are excellent for clean rooms and industries that require high levels of accuracy. Their lightweight and “pencil like” ergonomics makes them a suitable tool for most operators.

- Dynabrade Angle Grinders

Dynabrade angle grinders feature powerful motors and an ergonomic design, making them ideal for tasks that require both high performance and operator control. These are larger and more powerful than pencil or die grinders and are designed for medium to heavy stock removal.

Applications:

- Heavy Material Removal: Grind down thick welds or rough surfaces to achieve a smooth finish.

- Cutting Metal: With a proper Type 27 Cut Off Wheel installed, angle grinders can slice through rebar, bolts, and sheet metal with ease.

- Surface Conditioning: Coated abrasives such as flap discs or fiber discs can be used for finishing and polishing work.

Industries Where Pneumatic Angle Grinders Can Be Found Include:

Construction, aerospace, shipbuilding, and industrial maintenance.

Choosing the Right Grinder

When selecting a Dynabrade grinder, consider the following:

- Application Requirements: Are you grinding, polishing, deburring, or cutting?

- Material Type: Some grinders are better suited for metals, while others are designed for composites, wood, or plastics.

- Work Environment: Consider space constraints and operator safety when making your choice.

- Power Source: Pneumatic tools are generally lighter and more durable for continuous use, while electric models offer greater portability.

- Dust Considerations: Dusty work environments may call for a shrouded tool that can be connected to a wet dry vac or central vacuum system.

Final Thoughts

People in many fields trust Dynabrade grinders because they are accurate, dependable, and user-friendly. This grinder is ideal for nearly every job, whether it's finishing a weld, deburring a machined part, or polishing a mold. By understanding the various types and their optimal applications, workers can select the most suitable tool to enhance productivity and achieve consistent, high-quality results.

For help selecting the right Dynabrade grinder for your material removal application give us a call at (800) 608-5210 or info@intlairtool.com