Posted by John Levan on 14th Jan 2026

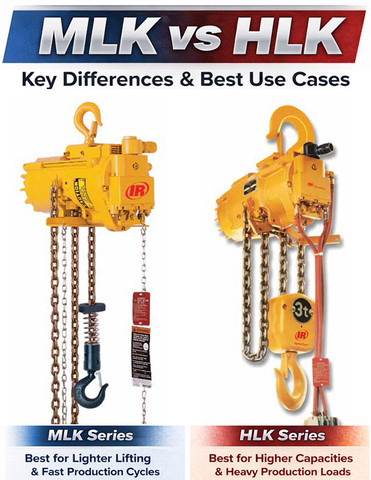

Ingersoll Rand MLK vs. HLK Air Hoists: Same DNA, Different Applications

Running production or maintenance in a shipyard or similar industrial setting requires an air hoist that looks impressive on a spec sheet but, more importantly, can withstand humidity, salt air, grit, weld smoke, and round-the-clock work without any out drama.

Ingersoll Rand created the Series MLK and Series HLK for that kind of world. They share a lot of design intent—high-duty-cycle capability, precise control options, and a rugged, serviceable build—but they offer different capacity ranges and have other subtle differences.

Both the Ingersoll Rand MLK and HLK Series Hoists are often found in the oil and gas industries as well as in waterfront, marine type settings.

The main differences and where each series is most useful:

Let’s start with the most practical distinction: lifting capacity ranges.

- MLK Series: roughly 550–2,200 lb. (250–1,000 kg) Works best for smaller assemblies, fixtures, valves, spools, and repetitive handling work where speed and cycle time matter.

- HLK Series: 2,200–13,200 lb. (1,000–6,000 kg) Excellent for the heavier end of the shipyard workflow, such as machinery components and structural parts.

That single range difference is usually enough to steer the decision. But there’s more nuance when you look at how industrial settings actually operate.

Duty cycle and production rhythm: both are built to run

Ingersoll Rand has positioned both families for severe-duty, high-cycle work. The company lists a 100% duty cycle with HMI duty classification A5 (severe duty) (also cross-referenced to FEM 2m) for MLK/HLK.

In plain terms, in contrast to electric hoists, Ingersoll Rand air hoists can work an entire shift without a “cool down” period. That translates to fewer bottlenecks for managers when a hoist becomes the limiting factor in a production cell.

Speed vs. "spotting" - MLK shines for fast cycles, HLK for controlled heavy lifting

Both series have high speeds and precise spotting, which is exactly what you need to keep takt time moving without sacrificing safety.

Where MLK tends to earn its keep is in high-speed production handling—the repetitive “lift, move, place, repeat” jobs where minutes add up across a shift. The MLK family also has “MLKS” slow-speed spotting models for finer control when alignment matters more than speed.

HLK is the step-up when the same cycle-time pressure exists, but the loads are heavier, and the consequences of drift, swing, or over-speed are more significant. HLK’s published model lineup shows lower-rated speeds as capacity climbs—An inverse relationship between capacity and speed is a common phenomenon when it comes to powered hoists.

Control and braking: the stuff maintenance cares about

From a maintenance manager’s point of view, two features matter every day: control feel and brake behavior.

Both MLK and HLK support pull-chain or pilot-pendant controls, and IR says that either allows for precision spotting.

Both series also use a self-adjusting, air-operated disc brake (spring-applied, air-released) and the IR service notes indicate wear testing to over 1 million cycles before replacement.

On the platform or in the shipyards, brake details matters because loads get held in awkward places—over jigs, into hatch openings, under cranes—all the while people fit, tack, or confirm alignment. A brake system designed for frequent cycling and holding is a big reliability win and of utmost importance when it comes to worker safety.

Chain and “mechanical heft”: HLK is built for higher loads

There is a notable mechanical difference between the MLK and HLK series: the HLK incorporates a larger chainwheel to accommodate a 3/8-inch-diameter chain and uses gearing suited to higher capacities.

That’s the kind of detail that shows up later as durability and longer wear life in heavy service—especially when your environment is not kind to consumables.

These are the kinds of details that separate the world class engineering of Ingersoll Rand lifting products from the” also rans”.

Spark-resistant options for explosive environments: when work in the “hot zone” isn’t optional

Since shipyard and oil and gas work often overlap with fuels, coatings, confined spaces, and hot zone, both the MLK and HLK are offered with spark-resistant variants:

- MLKR and HLKR are spark-resistant hoists for hazardous environments, featuring components such as bronze load hooks, bronze trolley wheels, and stainless-steel load chains, among other changes.

- IR also notes a practical reality: spark-resistant versions have reduced capacity and speeds due to the material differences and restricted motor setup.

So, if you’re specifying KR spark resistant models, plan the lift plan and cycle time accordingly—don’t assume you’ll get the same performance as standard units.

Which hoist is typically recommended in different industrial environments (general rule-of-thumb)?

- Choose MLK when your most significant pain is throughput on lighter loads—lots of picks per shift, frequent starts/stops, and a need for fast handling with reasonable control.

- Choose HLK when the pain is moving heavier components safely and repeatedly, and you want the same rugged, duty-cycle mindset, but in a higher-capacity.

Ingersoll Rand MLK vs. HLK Air Hoists: At-a-Glance Comparison:

| Feature | MLK Series | HLK Series |

| Rated Capacity Range | ~550–2,200 lb. (250–1,000 kg) | ~2,200–13,200 lb. (1,000–6,000 kg) |

| Typical Shipyard Use | Fixtures, valves, pipe spools, smaller assemblies, repetitive production lifts | Machinery components, structural parts, heavy modules, large subassemblies |

| Duty Classification | HMI A5 (Severe Duty), FEM 2m | HMI A5 (Severe Duty), FEM 2m |

| Duty Cycle | 100% duty cycle | 100% duty cycle |

| Lift Speed Philosophy | Higher speeds for fast cycle times; optional slow-speed spotting models (MLKS) | Controlled speeds scaled for heavier loads and safer placement |

| Spotting & Control Precision | Excellent fine control; ideal for repetitive alignment work | Excellent fine control with heavier load stability |

| Control Options | Pull chain or pilot pendant | Pull chain or pilot pendant |

| Brake System | Self-adjusting, air-operated disc brake (spring-applied, air-released); tested to 1M+ cycles | Same self-adjusting, air-operated disc brake design |

| Load Chain / Drivetrain | Sized for lighter loads and higher lift speeds | Larger chain wheel; supports 3/8-inch chain for higher capacities |

| Mounting Options | Hook mount or trolley mount | Hook mount or trolley mount |

| Spark-Resistant Versions | MLKR models available (reduced capacity/speed) | HLKR models available (reduced capacity/speed) |

| Best Fit Environment | High-cycle production stations where speed and repetition matter | Heavy-lift stations where control, durability, and safety dominate |

| Maintenance Perspective | Faster wear cycles due to speed, but easy service access | Heavier components, longer wear life under high loads |

In Summary:

If your team is constantly waiting on a hoist for light-to-midweight repetitive work, MLK units usually deliver better throughput.

If your bottleneck is heavy handling with strict placement requirements, HLK is the safer long-term choice—even if lift speeds are lower.

International Air Tool Company is an authorized distributor of Ingersoll Rand Lifting Products. We offer in person consultation throughout Southern California and Northern Mexico.

For further help choosing the right Ingersoll Rand Air Hoist for Your Industrial Lifting Application, give us a shout at (442) 515-3765 or drop us an email at info@intlairtool.com