Posted by Laxman Patel on 3rd Sep 2025

Cleco Assembly Tools: Precision, Power & Productivity

In today’s fast-paced manufacturing environments, every second counts — and every fastener matters. Whether in aerospace, automotive, heavy equipment, or industrial production, assembly quality can make the difference between operational excellence and costly rework. That's where Cleco assembly tools shine, delivering the precision, power, and productivity modern manufacturers demand.

A Legacy of Reliability

Manufacturers with assembly operations identify Cleco as a reliable brand because Cleco tools deliver precise torque control, comfortable ergonomics, and extended service life. Whether mechanical clutch or transducerized, Cleco assembly tools deliver reliable, high-quality results in production settings.

Cleco built its reputation through precise engineering and innovation, starting with pneumatic nutrunners and continuing with modern electric and cordless solutions. Cleco goes well beyond manufacturing standards to include automated systems, material removal solutions, and fastening tools.

Precision That Protects Quality

Assembly operations require torque accuracy as one of their most essential elements. Over-tightening fasteners results in thread stripping and component damage. Conversely, under-tightening leads to loosening, vibration problems, and complete system failure. The precise torque control mechanisms in Cleco tools allow operators to achieve exact specifications during every operation.

The digital and transducerized tools from Cleco provide operators with real-time feedback, programmable torque settings, and error-proofing features. The system guarantees that all fasteners will meet quality standards without causing production delays. The aerospace and automotive industries require absolute precision because safety is their top priority.

Power That Keeps Up With Production

Manufacturers need to maintain a precise equilibrium between achieving sufficient fastening power and protecting operator safety and comfort. The advanced motor designs of Cleco tools enable strong performance by delivering high torque output in lightweight, compact packages.

Pneumatic tools from Cleco serve as primary equipment for heavy-duty operations because they supply the continuous power required for running high-volume production lines. Their battery-powered tools offer both hose-free operation and strong fastening capabilities while providing steady torque output. Furthermore, most cleco corded electric and cordless tools can be used with our without a controller, so rundowns may be recorded and stored for liability purposes.

The result? Cleco tools achieve faster cycle times and reduce delays while maintaining their ability to match the production speed of modern manufacturing.

Productivity Through Ergonomics and Efficiency

Productivity extends beyond quick work because it involves minimizing worker fatigue while maintaining consistent results and ensuring workplace safety. Cleco dedicates itself to designing products with ergonomics in mind to minimize vibration and noise levels and reduce operator fatigue. The combination of balanced tool weight with comfortable grips and reduced trigger force enables operators to maintain better control while working extended shifts without excessive fatigue.

Using manufacturing execution systems (MES) with Cleco tools enables the capture and analysis of fastening data. The system allows for process optimization and immediate quality issue detection, which supports continuous improvement initiatives that are essential for lean manufacturing goals.

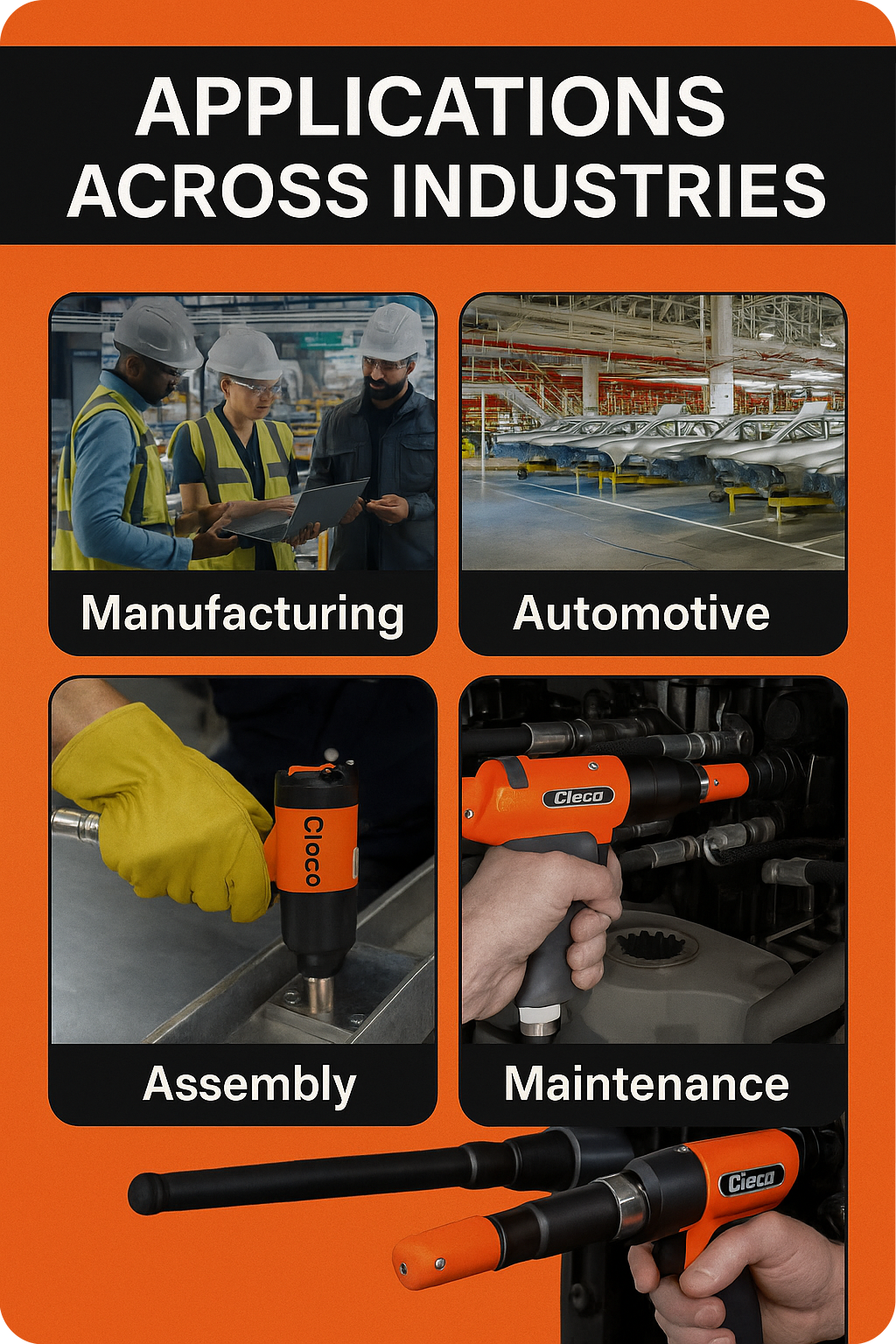

Applications Across Industries

Cleco assembly tools function best for applications that require exact fastening. The main industries that utilize these tools include:

- Aerospace: High-precision torque management for the construction, upkeep, and repair of aircraft.

- Automotive: Cleco provides fast and reliable service throughout the entire process from interior trim installation to powertrain assembly.

- Heavy Equipment: Sturdy instruments made to withstand harsh environments, high torque, and big bolts.

- Electronics & Appliances: Low-vibration, lightweight instruments perfect for delicate assembly jobs.

The tools receive specific design modifications to fulfill the unique torque requirements, cycle speeds, and material specifications of each industry sector.

Commitment to Innovation

The engineering teams at Cleco make ongoing improvements to their designs, which address emerging manufacturing obstacles. The company advances its cordless technology while merging with Industry 4.0 systems and develops new error-proofing methods to decrease assembly defects.

The smart fastening systems track all fastening operations while detecting irregularities and blocking production progress until fastening specifications are met. The system enhances quality standards while creating digital records that meet the increasing traceability needs of regulated industries.

The Bottom Line

The modern manufacturing industry depends on Cleco assembly tools because they deliver proven solutions for data-driven operations at high speeds with strict quality standards. Cleco offers assembly solutions that match your needs by providing tools that deliver precision quality protection, powerful performance, and efficient productivity.

Cleco assembly solutions provide customized options to meet your requirements for speed, repeatability, ergonomics, and digital integration. The outcome produces both faster fastening and more intelligent manufacturing through tools that contribute to excellence in delivery.

High-quality assembly tools purchased as a strategic investment result in improved production quality, decreased rework, safer manufacturing operations, and increased efficiency. Cleco consistently demonstrates its ability to meet manufacturing challenges.