27th Oct 2023

Mitigating Energy Waste: Diagnosing and Controlling Compressed Air Leaks in Production Lines

In various industrial settings, meticulous attention to detail is paramount for success. In this article, we aim to equip readers with essential insights into the detection and reduction of energy-wasting compressed air system leaks. Remarkably, the size of these leaks directly correlates with production costs, which can accumulate significantly over time. Proficiency in identifying the signs of a compressed air system leak is vital for minimizing their impact and averting unnecessary expenses.

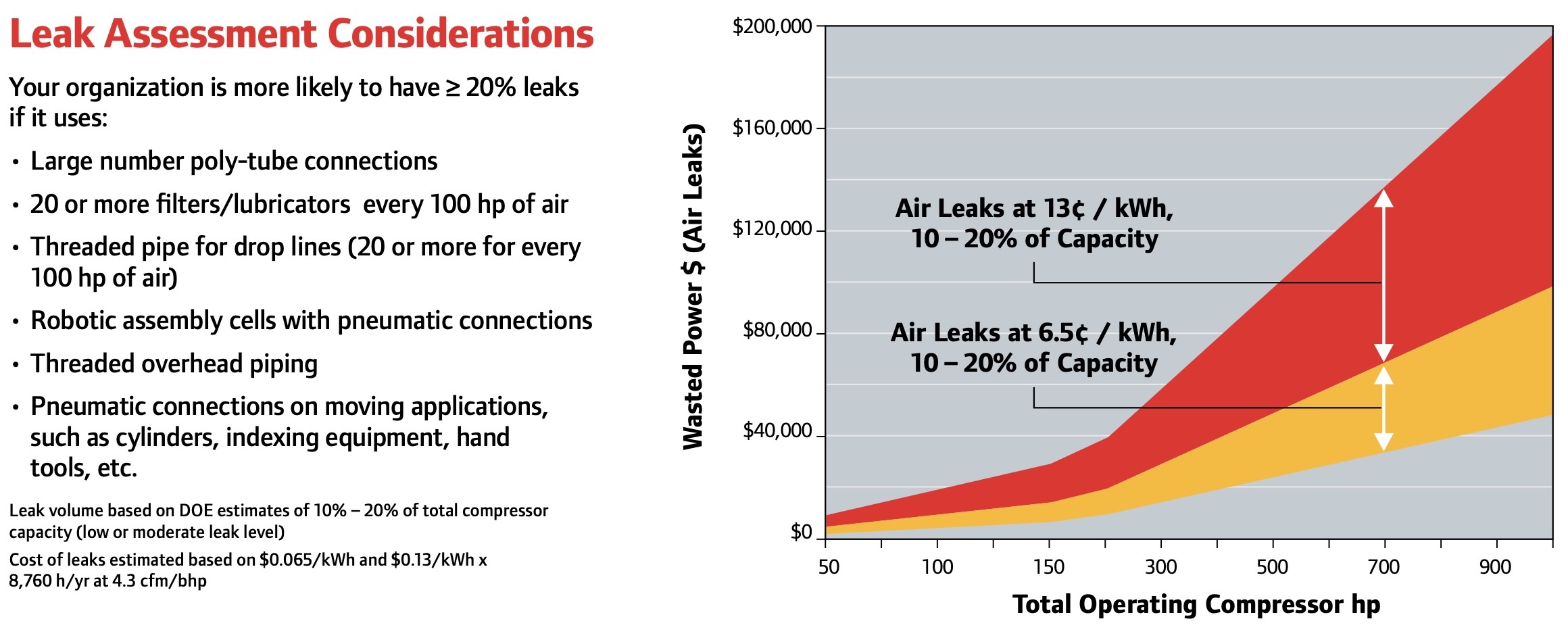

Understanding the Economic Impact of Air Leaks

Compressed air, a precious resource, is intrinsically costly, but the presence of leaks within a compressed air system amplifies these costs exponentially. Typically, these leaks manifest at joints, connections, and vulnerable areas of the system, such as pipe joints, disconnects, and threaded sealants. Additionally, common leak sources encompass manufacturing equipment, couplings, hoses, tubes, and pressure regulators. Unattended leaks also facilitate the entry of moisture into the compressed air system. As air escapes through leaks, moisture is simultaneously drawn into the compressor, jeopardizing the purity of the air supply. Moreover, leaks induce a drop in overall system pressure due to the loss of air, necessitating increased energy consumption to maintain optimal productivity levels.

Calculating the Cost of Leaks

The precise escalation in energy costs due to leaks may vary depending on the specific characteristics of the compressed air system. Nevertheless, a reliable estimate can be derived using a straightforward formula based on the principles of compressed air flow through an orifice. By identifying the orifice size and the pressure at which air escapes, you can determine the flow rate, usually measured in cubic feet per minute (cfm). Considering that most compressors typically deliver approximately 5 to 6 cfm per kilowatt (kW), you can calculate the annual cost of the leak using the following formula:

Cost of Leak ($/year) = (CFM / 5.5 kW) × Hours of Operation per Year × Power Costs ($/kW-hr)

Recognizing and addressing compressed air system leaks is paramount in the ongoing pursuit of waste reduction and cost efficiency in various industrial applications.

Detecting and Addressing Air Leaks

Leaks are an inevitable challenge in any system, and the key question is: how many leaks does the system have? To combat the decline in energy efficiency and the rise in operational costs, it's crucial to become proficient in conducting leak assessments. Air leaks are often elusive to the naked eye, making it necessary to employ alternative methods for their detection. While a casual walk through the facility can reveal larger, audible leaks with a distinct hissing sound, smaller, more common leaks demand more specialized tools.

- Detecting Larger Leaks: For larger leaks that produce noticeable hissing sounds, a simple stroll through the plant can be an effective method of detection. This hands-on approach allows for the immediate identification of significant leaks that may be affecting energy efficiency and increasing operational costs.

- Identifying Subtle Leaks: However, smaller and less audible leaks require more advanced methods for detection. An ultrasonic acoustic detector is a valuable tool for identifying high-frequency hissing sounds associated with less noisy but financially impactful system leaks. Ingersoll Rand offers ultrasonic leak detection services that utilize visual tags for easy identification of leak sources.

As an alternative, an effective self-assessment method for detecting leaks is brushing soapy water on suspect areas to reveal the air leaks. While a reliable method for identifying leaks, it is not the most expedient.

Air Leak Assessment, Remediation and Maintenance

Conducting routine assessments to identify and remediate air leaks is crucial for optimizing energy efficiency and cost-effectiveness in various industrial settings. While internal inspections of a plant for leaks are a valuable practice, there are additional approaches to consider. Consulting external experts to perform professional compressed air system assessments on a regular basis offers distinct advantages. These assessments encompass not only measuring energy consumption and system output but also quantifying air loss due to leaks and investigating concealed sources of waste.

Moreover, routine leak assessments can unearth larger systemic issues. For instance, if a previously repaired leak reoccurs, it could signify an underlying problem in the system, such as corroded materials or worn components, allowing plant managers to address root causes proactively.

Beyond Leak Detection

Identifying leaks is just the initial step in the solution. Once leaks are pinpointed within the system, plant managers must determine how to efficiently rectify the problem without disrupting production. Following an evaluation of losses and performance issues attributed to system leaks and the identification of leaks throughout the compressed air system, assessment engineers can deliver a comprehensive report on waste contributors. This report would include recommended courses of action and guidance on the most efficient approach to manage areas of waste in a timely and cost-effective manner. Leveraging extensive industry experience and expertise, assessment engineers can significantly reduce waste within a compressed air system, extending the benefits beyond addressing leak-related costs.

In conclusion, effectively reducing energy consumption resulting from air leaks is imperative for streamlined production in various industrial applications. By understanding the economic impact of leaks and employing the provided formula, facilities can take proactive measures to mitigate energy waste, safeguard air quality, and optimize their production processes.

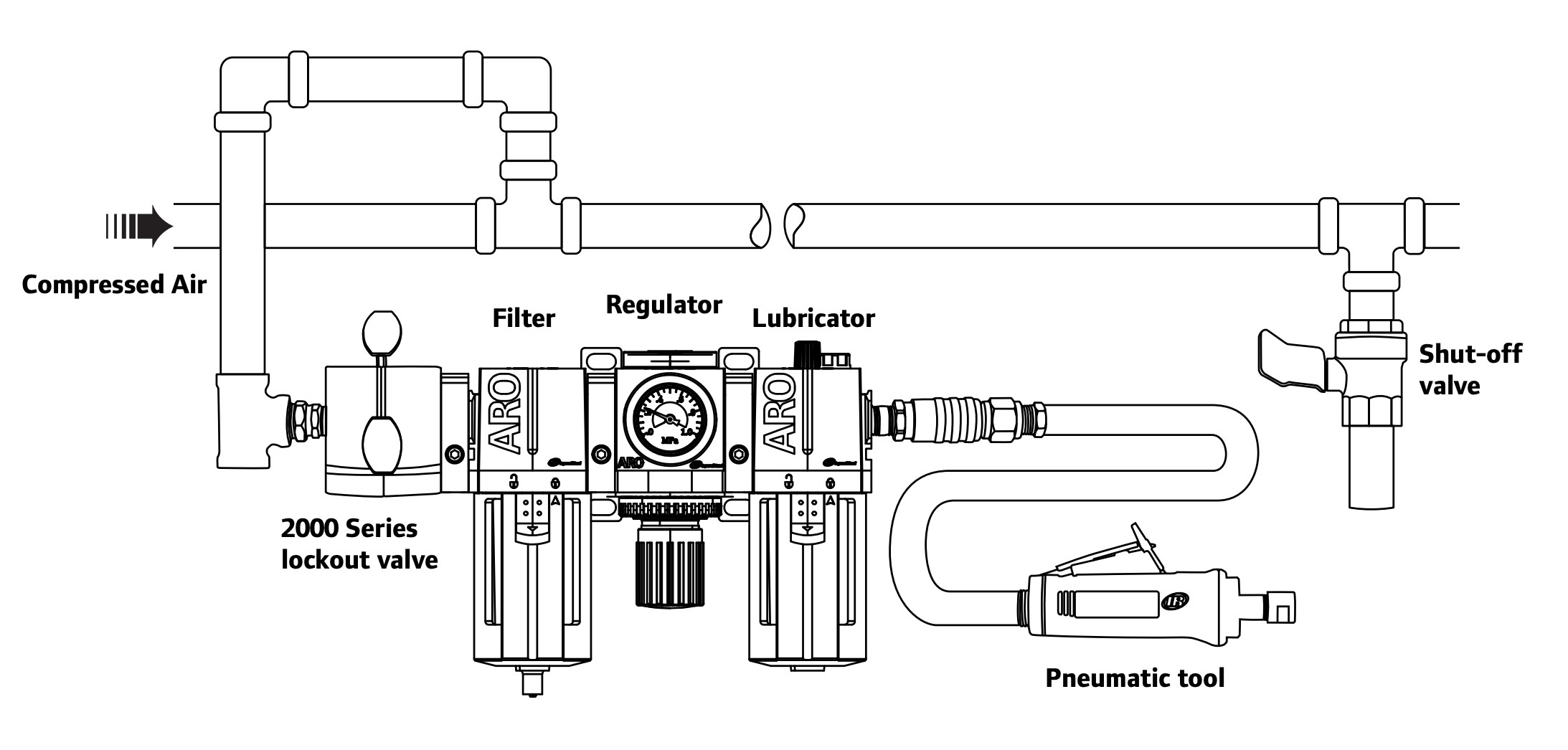

If you want to learn more about optimizing air tool performance, check out our two part article on Pressure and Air Flow, and Proper Conditioning of Compressed Air where we cover how using a Filter Regulator Lubricator (FRL) can help keep the compressed air clean to ensure best performance and help extend tools life.

For more information give us a call at (800) 608-5210 or email info@intlairtool.com