Posted by John Levan on 20th May 2025

Ingersoll Rand Air Motors in Industrial Environments | Overview, Applications, Performance Considerations, Service Options

For over 125 years, Ingersoll Rand has set the global standard in delivering reliable, high-performance air power solutions. A pioneer in pneumatic technology, the company offers a broad line of Ingersoll Rand air motors, including vane and piston types, that users trust across various industries for their flexibility, durability, and efficiency. Ingersoll Rand air motors deliver unmatched performance where electric or hydraulic systems may fall short, whether in manufacturing, material handling, or harsh environmental applications.

Overview of Ingersoll Rand Air Motors

Ingersoll Rand power motors convert compressed air into rotary mechanical power. They are a safer, cooler, and more robust alternative to electric motors, especially in demanding or hazardous environments. They come in various configurations and sizes to match a wide range of torque, speed, and horsepower requirements.

Ingersoll Rand offers more than 200 cataloged models and maintains a library of hundreds of application-specific solutions developed over decades. This extensive selection lets end users confidently specify the ideal air motor for nearly any task or operating condition.

Key Features of The Air Motors

Wide Range of Models

Ingersoll Rand air motors are available in:

- Reversible and non-reversible options

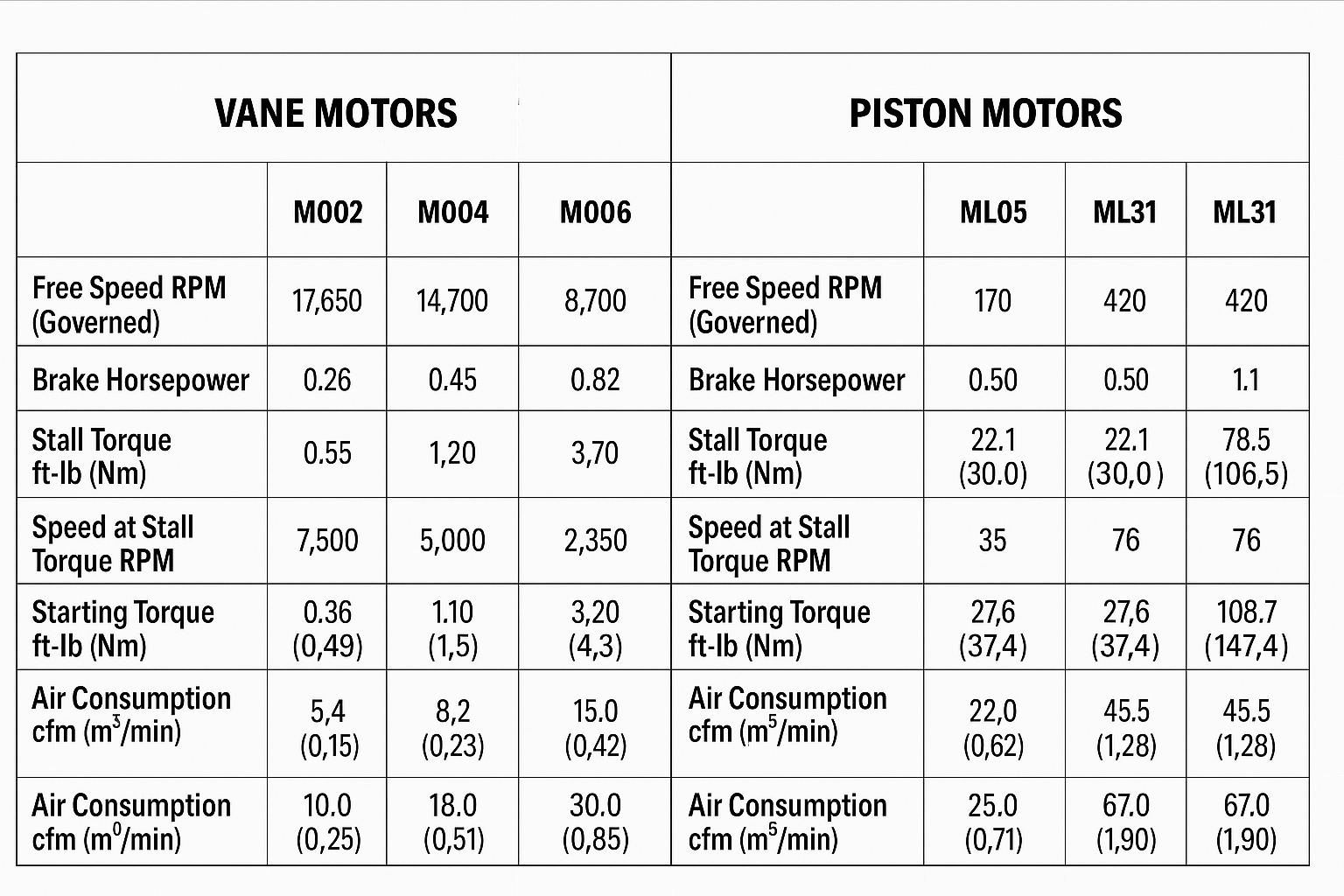

- Vane or radial piston configurations

- Geared and non-geared versions

- Horsepower ratings from 0.10 to 30 HP

- Speeds from 23 RPM to 26,000 RPM

- Torque outputs from 0.10 ft-lb to 1,090 ft-lb

Durability and Safety

These motors withstand overload, stall, and extreme environments. Unlike electric motors, Ingersoll Rand power motors won't overheat or burn out when pushed to the limit. They are also ideal for explosive or flammable work zones with no electrical components, eliminating the risk of sparks.

Efficient Speed and Torque Control

Through simple air pressure regulation or valve adjustments, users can easily fine-tune the speed and torque of an Ingersoll Rand air motor without needing expensive control systems. Starting, stopping, and reversing are nearly instantaneous, improving response time and operational flexibility.

Cool and Clean Operation

Our air motors naturally cool during operation, reducing the risk of overheating and making them perfect for hot, dusty, or wet environments. Since they do not have hydraulic fluids or electrical components, they are cleaner and require less maintenance than traditional alternatives.

Compact and Lightweight Design

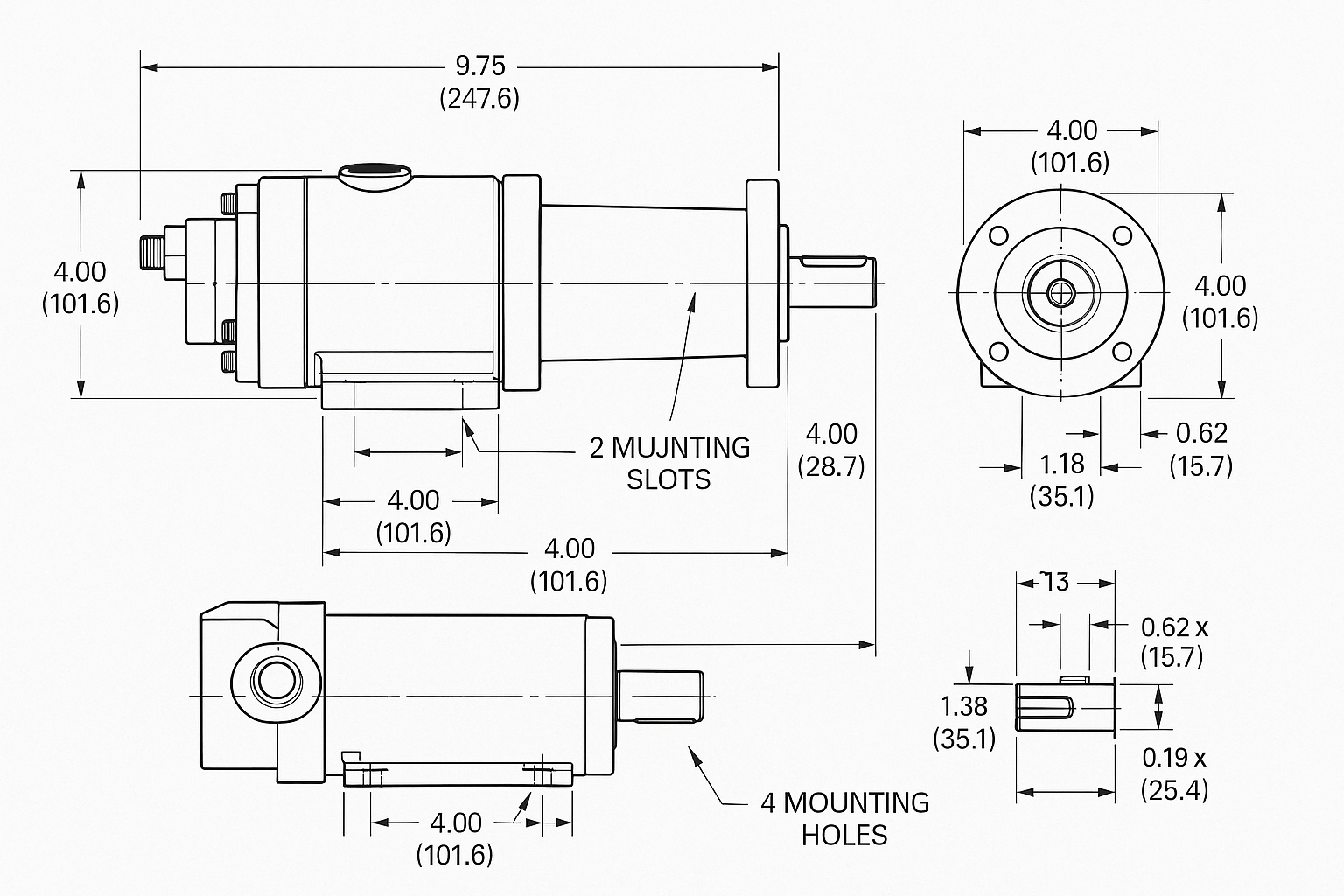

Thanks to their high power-to-weight ratio, Ingersoll Rand air motors are smaller and lighter than equivalent electric motors. They are easier to install and have improved design flexibility in tight spaces.

Service and Support

Ingersoll Rand repairs air motors at their Dallas, Texas based service center. Ingersoll Rand ensures users receive expert repairs with genuine parts backed by a 90-day repair warranty. All work is performed by fully trained IR technicians using OEM-approved equipment.

Motor Types and Applications

- They are popular due to their simplicity and cost-effectiveness.

- Smaller and lighter than Ingersoll Rand piston motors of equivalent power.

- Can operate in almost any position.

- Ideal for high-speed applications requiring low-to-medium torque.

- Preferred for low-speed, high-torque applications.

- Excellent starting torque and speed control.

- Best suited to "lugging" heavy loads at slow speeds.

- Typically operate in a horizontal position.

Reversible vs. Non-Reversible

- Non-reversible motors provide slightly higher speed and torque.

- Reversible motors offer flexibility for applications requiring bi-directional operation.

Performance Considerations

Air Pressure

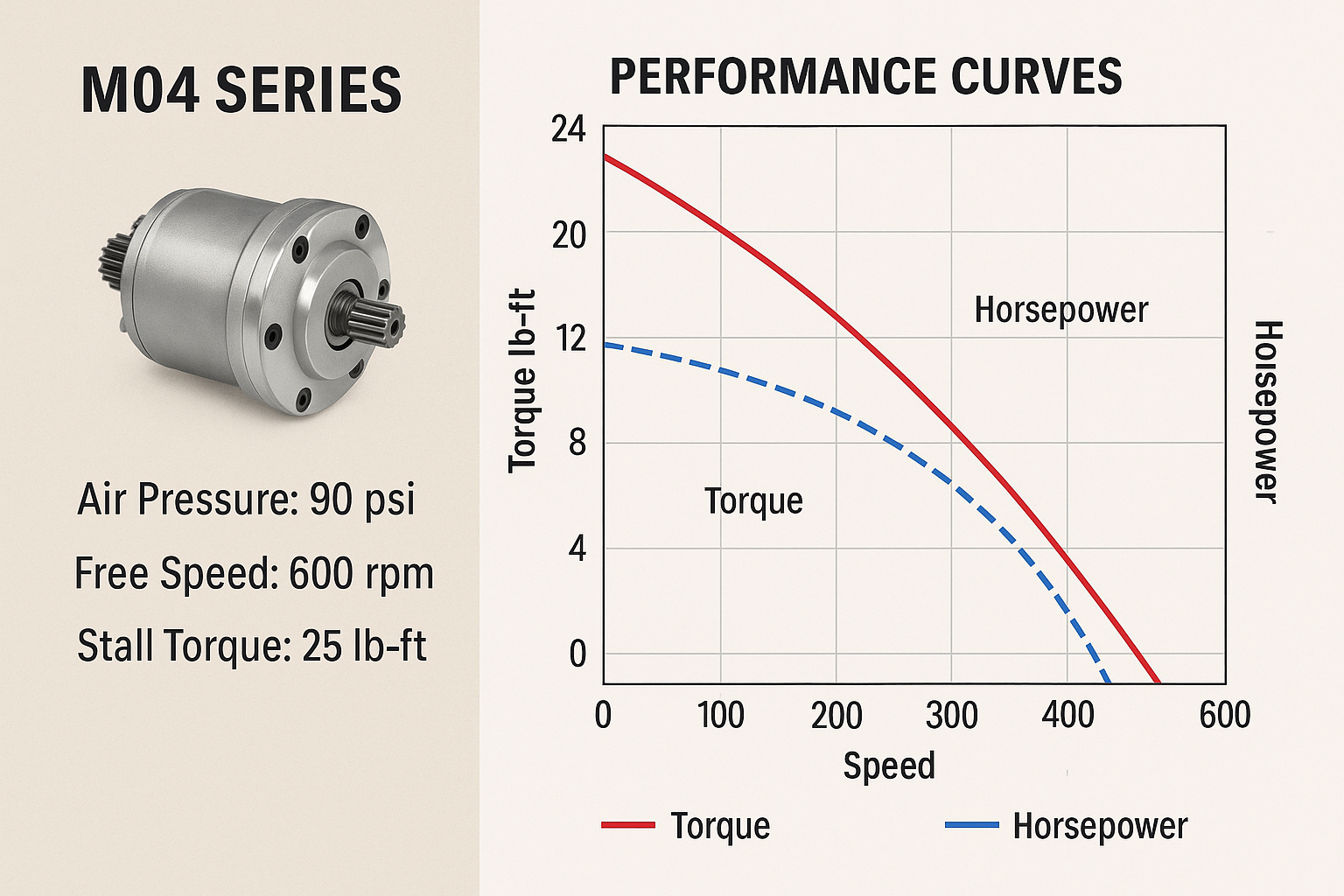

Ingersoll Rand motors run at 90 PSI but can operate at various pressures. They recommend motor sizes at 70% of the lowest expected pressure to accommodate starting loads and prevent underperformance.

Speed and Torque

- Peak horsepower for ungoverned motors occurs at ~50% of free speed; for governed models, it peaks at ~80%.

- The starting torque is roughly 75% of the stall torque.

- Base your selection on the desired running speed and torque, not free (unloaded) speed.

Load Conditions

To avoid premature wear, consider overhung loads when applying pulleys or gears to a motor shaft. Ingersoll Rand provides precise performance data to guide proper sizing and selection.

System Compatibility

Ensure the compressed air system delivers the necessary pressure and volume (CFM) under load. Inadequate supply or exhaust restrictions can significantly degrade performance.

Benefits of Ingersoll Rand Air Motors

- Enhanced Safety: No sparks, overheating, or hydraulic leaks are ideal for explosive and hazardous environments.

- Operational Reliability: Resistant to overload, stalling, and environmental extremes.

- Flexible Performance: Easily adjustable speed and torque without complex controls.

- Reduced Maintenance: Simple construction and cool-running design lower the risk of mechanical failure.

- Design Freedom: Lightweight, compact motors allow more efficient system layouts.

- Environmental Resilience: Performs reliably in hot, wet, or dusty surroundings.

- Comprehensive Support: Backed by expert service centers, fast turnaround, and genuine IR parts.

Conclusion

Whether replacing an electric motor, powering a conveyor, or driving a process tool in a hazardous location, Ingersoll Rand air motors offer a rugged, efficient, and flexible solution. With their wide range of sizes and configurations, including high-performance Ingersoll Rand piston motors and compact vane designs, these air motors are the go-to choice for industrial designers and engineers worldwide.

For technical support, product selection, or custom solutions, International Air Tool Company, your authorized Ingersoll Rand distributor is ready to assist, backed by over 20 years expertise in air powerered tools and equipment.