5 Reasons Manufacturing Professionals Choose Coffing Electric Hoists

Posted by Natasha Teymourian on 18th Mar 2019

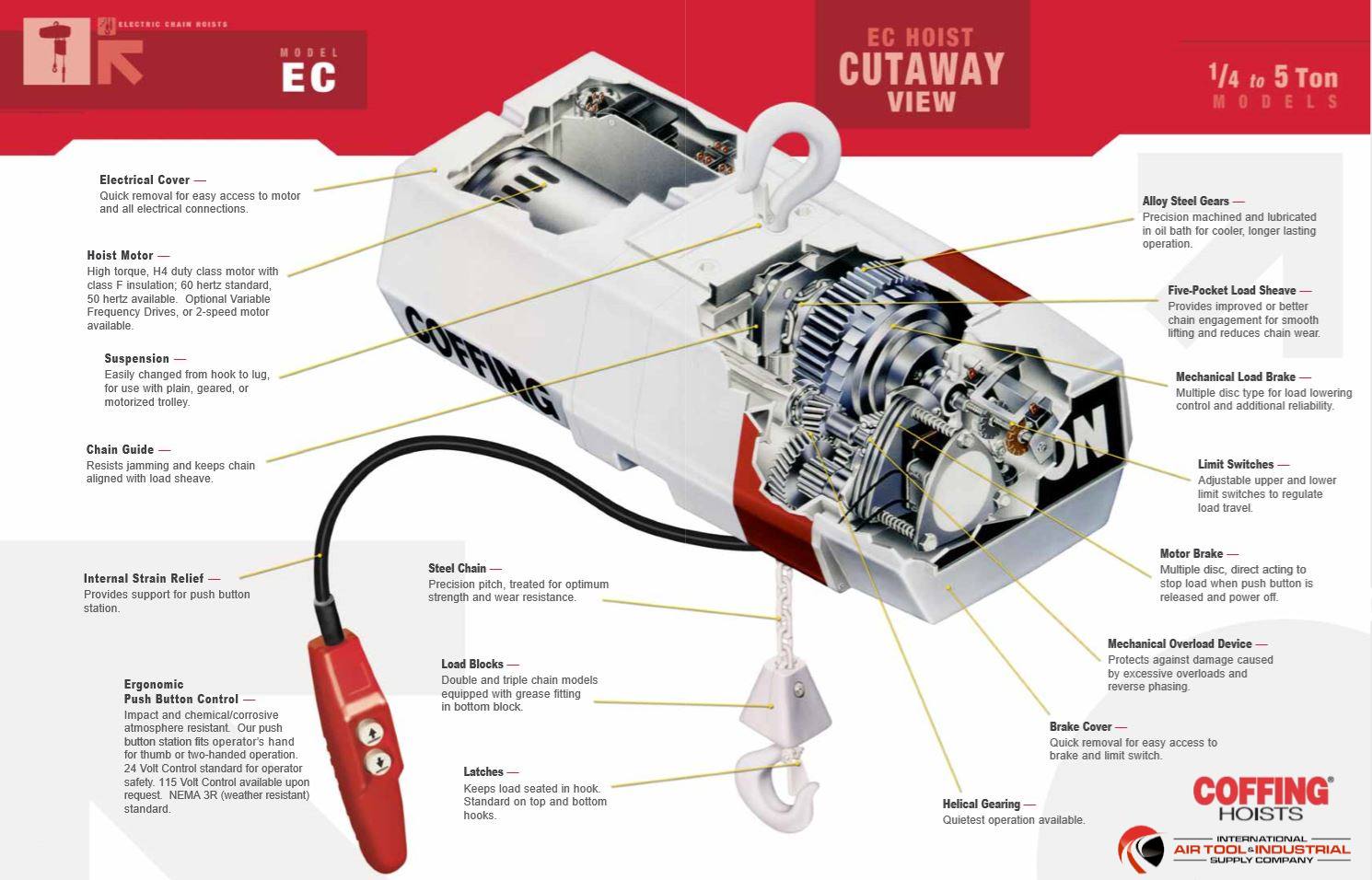

We all know and love our traditional Manual Chain Hoists (AKA: Chain Falls). They have a low initial price point, are well suited to lighter lifting, and don't require electricity or compressed air. While there are some definite advantages to using traditional manual hoists, Coffing’s EC Series Electric Hoists are engineered with both high performance and versatility in mind.

Coffing Electric Hoists are designed for use on a variety of applications and don’t always have to be used exclusively with the heaviest loads to be lifted – they can be used for smaller scale projects as well (despite the conversation in our last article, where we explored the larger-scale NASCAR racecar production of their parent brand, CM/Columbus Mckinnon).

Let's take a look at five advantages of using a Coffing Electric Hoist:

Increased Productivity

The first advantage of using an Electric Chain Hoist is simple: electric hoists are more powerful, effortless, and faster than manual chain hoists. Electric Hoists take the stress of lifting away from the operator and allow heavy materials to be lifted vertically and then moved horizontally if used in conjunction with a trolley.

Available with a variety of suspension options, the Coffing EC Hoists work well with rigid or swivel top hooks, lugs, plain, geared, and motorized trolleys.

More Productivity Features:

- Five-Pocket Load Sheave: Provides smoother lifting, reduces chain wear, and increases chain and sheave engagement 25% (over hoists with conventional four-pocket sheaves)

- Panel Plate: Get easy access to controls and motor leads for changing voltage on dual-voltage motors or performing hoist maintenance. Connection wires are numbered to assist with maintenance.

- Limit Switches: Adjustable to regulate upper and lower load travel. Brass nuts are standard for improved switch setting and repeatability. Stainless steel limit switch shaft standard.

Higher Capacity Loads

With rated loads from ¼ ton all the way up to 5 tons, Coffing EC Model Hoists make it possible to comfortably lift a variety of different weight loads. Their lifts vary, too – with 10, 15, and 20-foot standard lifts available and a standard push button drop that's 4-feet less than the hoists lift.

More Features:

- Gearing & Transmission: First stage helical gearing on EC small frame; first and third stage helical gearing on EC large frame. Transmission gears are precision machined of alloy steel and run in an oil bath for longer, quieter operation.

|

|

|

Shop Coffing EC Hoist Trolleys here. |

Lower Cost Over the Long Run

Increased efficiency and less stress on the operator helps lower workplace expenses. Once installed, the high carrying capacity saves manpower. Coffing hoists also come with a lifetime warranty on defects in materials and workmanship.

Increased Safety

Coffing EC Hoists were designed for safety: they incorporate a mechanical load brake, motor brake, and overload clutch as standard. Coffing Hoists offer the option of a large frame design that's stocked full of strength and load bearing housings of ductile iron construction. There's also a lighter weight option with non-load bearing housings of cast aluminum alloy and a small frame design (for motors up to 1 HP). Call for details (800) 608-5210.

More Safety Features:

- Mechanical Load Brake: Weston type brakes control load lowering and prevent load drift. Holds rated load independent of multiple disc motor brake.

- Multiple Disc Motor Brake: Heavy duty, direct acting design for positive load spotting and holding.

- Overload Clutch: Protects hoist, operator, and supporting structures from damaging overloads, chain jamming, and reverse phasing.

- Chain End Stop Assembly: Fits below dead end link on lifting chain for added measure of safety.

Durability

When well-maintained, electric hoists can serve you for many years. These Coffing Hoists are specifically built in compliance with ASME/ANSI B30.16, and CSA standard. Keep your machine in good condition with an annual inspection and cleaning.

More Durability Features:

- Solid State Starting Switch: Standard on single phase units. Provides greater reliability and starting consistency than centrifugal switches. Fewer components to wear out or fail.

- Ergonomic Designed Push Button Station: Fits operator's hand for thumb or two-handed operation. 24 Volt Control available upon request. NEMA 3R (weather resistant). Constructed of glass-filled nylon for severe impact and chemical/corrosive atmosphere resistance.

Check out a configured Coffing EC Hoist in action:

Speed up your production while decreasing your operating costs, for years to come.

Still interested in a manual chain hoist? No worries – we can get you one of those too. Reach out to our team at 800-608-5210 or info@intlairtool.com.

Already have a Coffing Hoist? What have you done with it? We'd love to see!